Exaddon blog

Latest News & Collaborations

Articles / Press Releases / Media

Takeaways from Exaddon's Award-winning Trip to SWTest USA 2025

Earlier this year, Exaddon attended SWTest USA, the premier semiconductor wafer test event in the world. Exaddon CEO Edgar Hepp demonstrated how the use of micro3D printing can deliver ultra-low leakage probe cards for parametric/WAT test.

The packed industry audience voted the presentation Most Inspirational Presentation of the event. Read Edgar's takeaways from the event here.

Georgia Tech Publishes Breakthrough Sub-THz Research with Exaddon micro3D Print Technology

The first-of-its-kind low-loss shielded interconnect design paves the way for next-generation solutions, thanks to the template-free print capabilities of the Exaddon CERES print system.

Georgia Tech's research has made waves in the mmWave and sub-THz community.

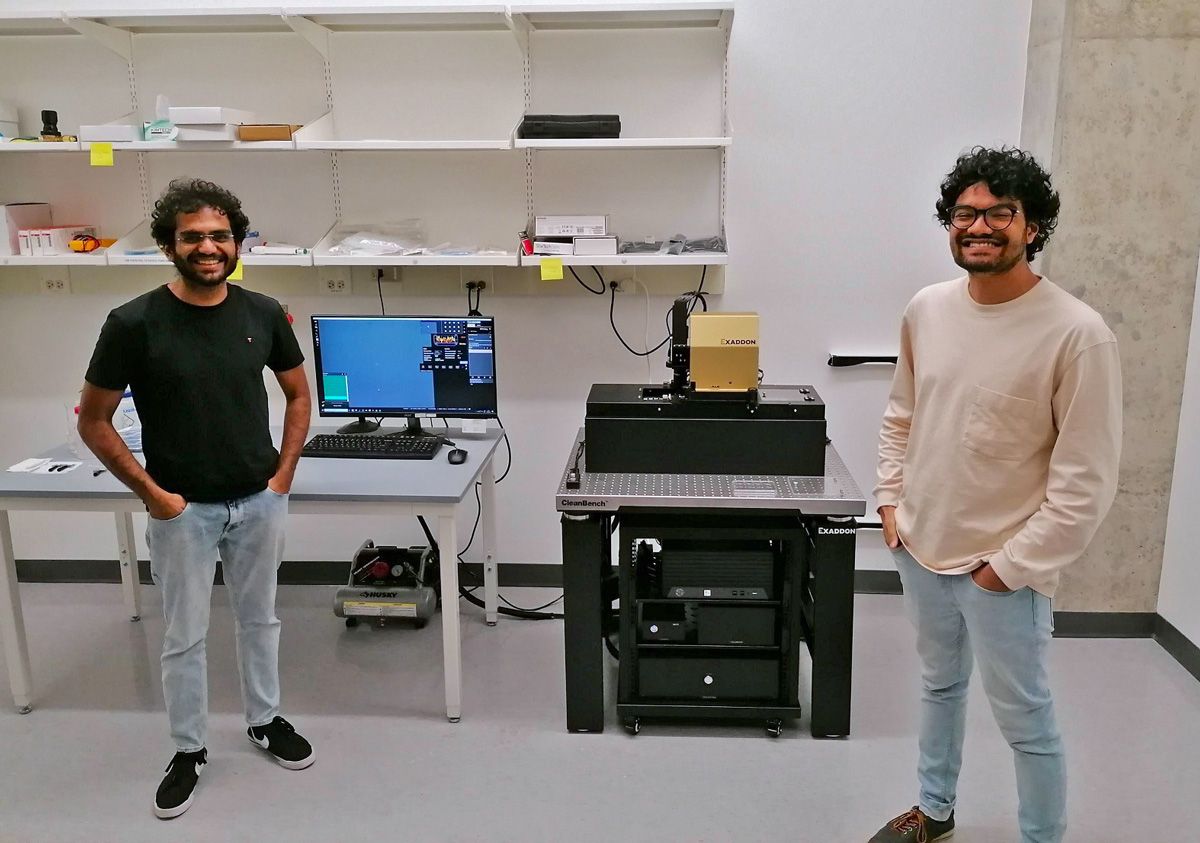

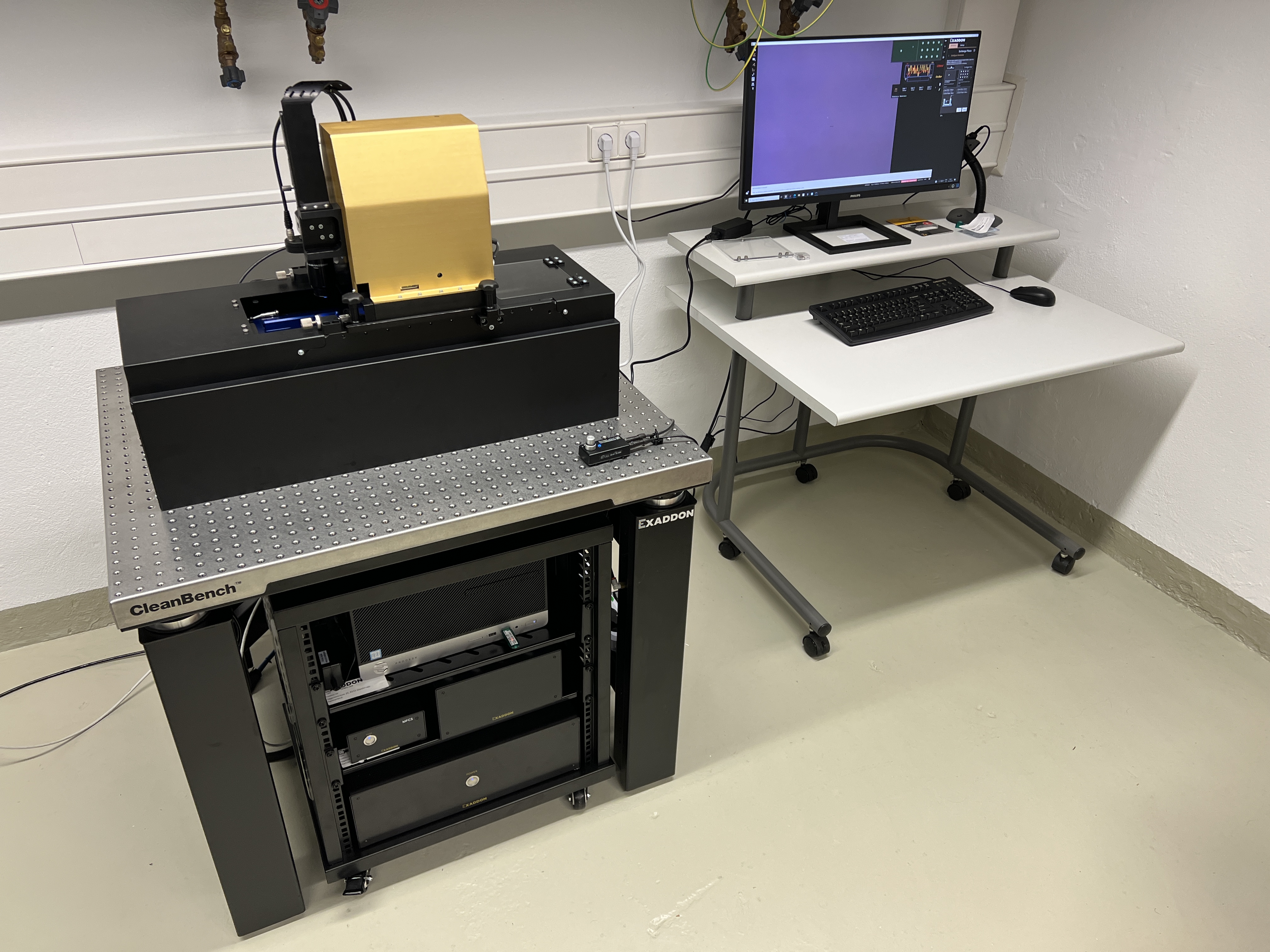

Karlsruhe Institute of Technology (KIT) Purchases CERES Print System for THz Research

The CERES system is installed at Institut für Hochfrequenztechnik und Elektronik, Karlsruher Institut für Technologie, and will be used for research into various high frequency (THz) applications.

The installation marks another positive milestone in Exaddon's mission to bring µAM technology to academic institutions with close ties to industry.

Cardiff University Purchases CERES Print System for Semiconductor Research

Exaddon's unique technology installed in the Translation Research Hub - a 12,000m2 facility constructed to trial, establish, and scale innovative compound semiconductor devices.

The installation marks another positive milestone in Exaddon's mission to bring µAM technology to academic institutions with close ties to industry.

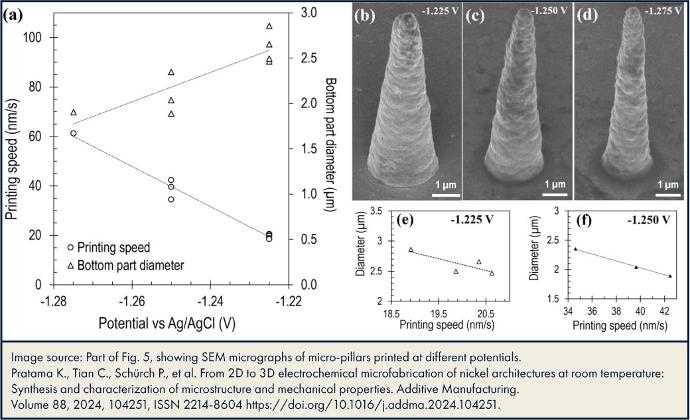

Breakthrough in Room Temperature 3D Microprinting of Nickel by Exaddon and EMPA

Exaddon and EMPA's latest breakthrough research showcases the CERES system's ability to 3D print nickel at microscale sizes at room temperature.

Published in Additive Manufacturing, the open-source paper is a very promising step forward in the direct printing of nickel.

Exaddon Present at SWTest USA 2024

Following Exaddon's attendance and award-winning presentation at SWTest Asia last year, we were invited to speak at SWTest USA, the foremost microelectronic wafer and die level testing conference in the USA.

Exaddon CEO Edgar Hepp presents his thoughts about a very successful trip to the heart of microelectronics testing.

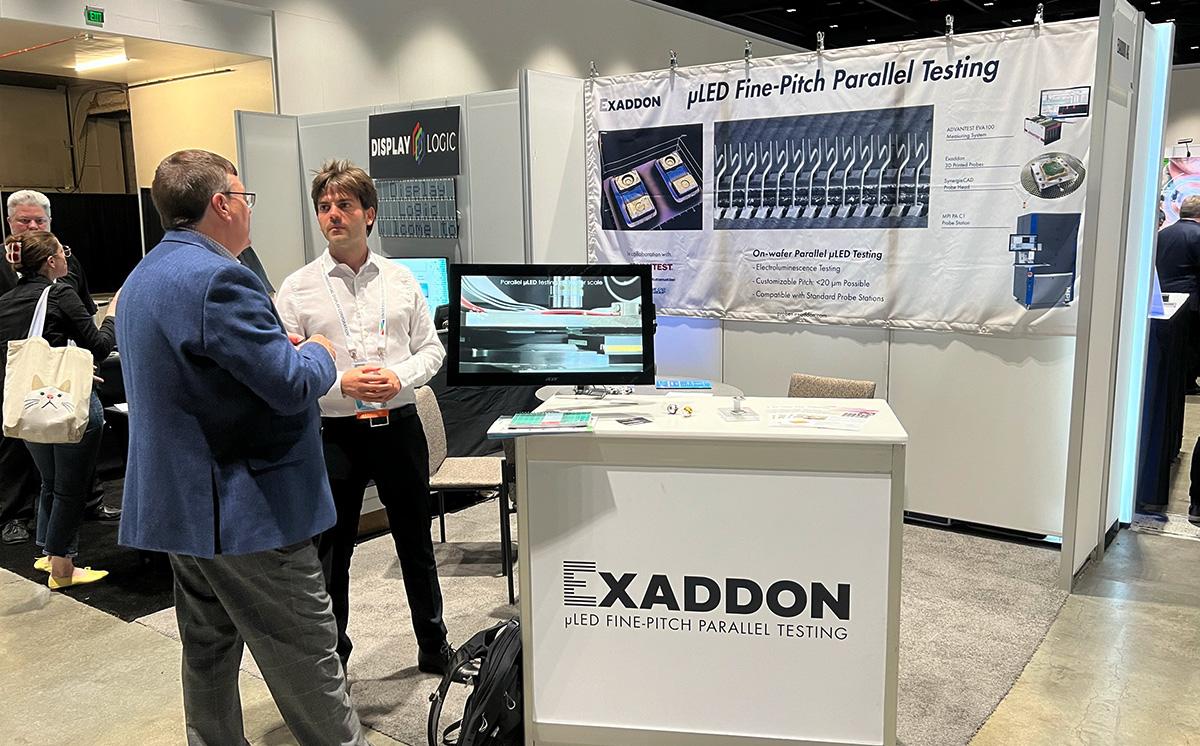

Exaddon at Display Week 2024

Display Week is the world’s largest technical symposium and exhibition for emerging tech in the global electronic display industry.

Exaddon travelled to San Jose, California to present our industry-first μLED Fine-Pitch Parallel Testing solution; namely 3D-printed probes for electroluminescence testing of microLEDs at wafer scale.

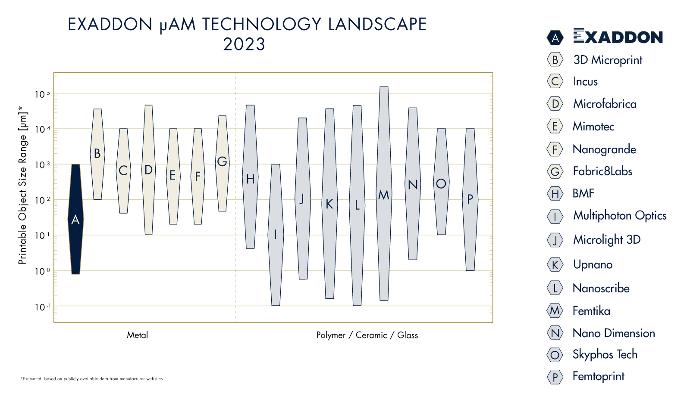

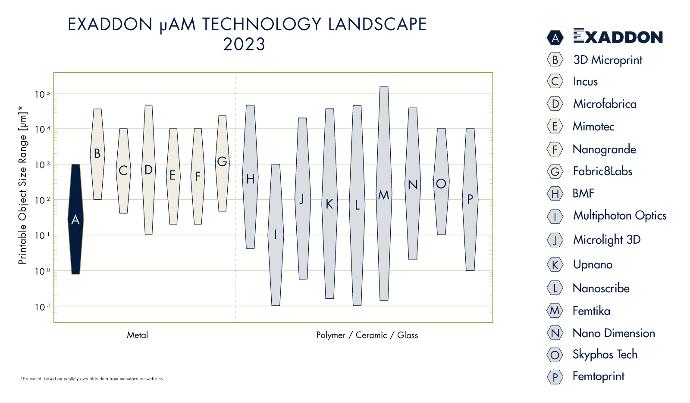

Microscale Additive Manufacturing Landscape 2023 - Exaddon Analysis

Explore the 2023 edition of our microscale AM landscape analysis, which surveys the providers and technologies within this truly innovative space.

Discover each provider's technology, including method of printing, materials used, object size range, and other relevant dimensions. Conclusions from our analysis are on the final page.

Excellent Media and Industry Response to Exaddon 3D Printed Probe Launch

News of Exaddon's 3D microprinted probes was very well received by media outlets across additive manufacturing, microLED, and display, as well as by big name companies within the wafer probing and display industries.

The positive news response reinforces the excellent conference feedback and "Best Data Presentation" award received at SW Test Asia, showing the promise of this innovative use of 3D microprinting.

Exaddon Exhibit and Present at SW Test Asia 2023 in Taiwan

Exaddon attended SW Test Asia 2023 to exhibit and present the new wafer probing application to an audience of the biggest names in semiconductor probe testing.

The presentation was awarded "Best Data Presentation", and shows the significance and potential of this innovative approach to going beyond fine pitch.

Beyond Fine Pitch: Exaddon Industrial Semiconductor Testing Application Launched!

Exaddon has developed the ability to 3D microprint high conductivity probes for use in fine-pitch semiconductor wafer probing, halving the current industry pitch limit and opening up huge possibilities for chip designers and testers alike.

Discover the details and new microsite.

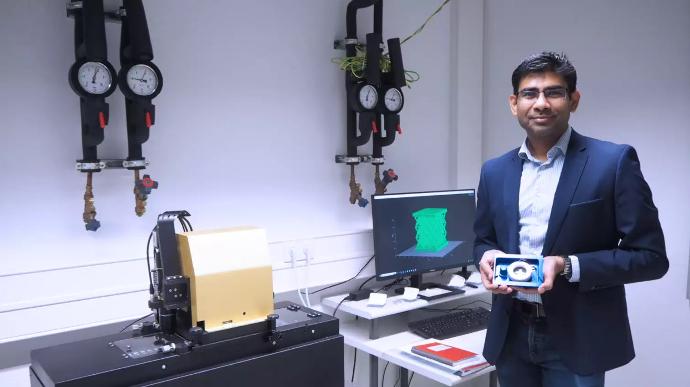

Georgia Tech Purchases Exaddon CERES Print System for Additive Micromanufacturing Research

Georgia Tech research teams can now print highly conductive metal structures in shapes that are impossible with other technologies.

The purchase adds Exaddon’s unique µAM (additive micromanufacturing) capabilities to Georgia Tech’s already extensive range of microelectronics and nanotechnology equipment.

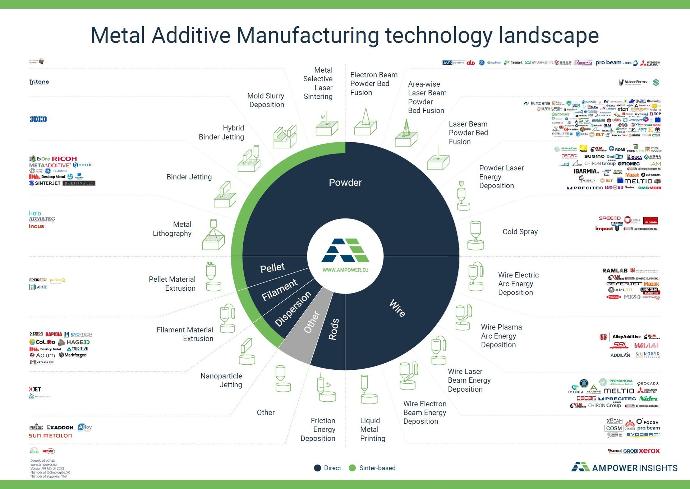

Exaddon Features in AMpower Metal AM Technology Landscape 2023

AMPOWER Insights have published the latest version of their long-running "Metal Additive Manufacturing technology landscape", and d

espite the many densely populated categories present, Exaddon can be found in the bottom left corner under

the label of "Other". Why is that?

Microscale additive manufacturing applications require extraordinarily accurate and precisely regulated print technology, and this is where Exaddon comes in.

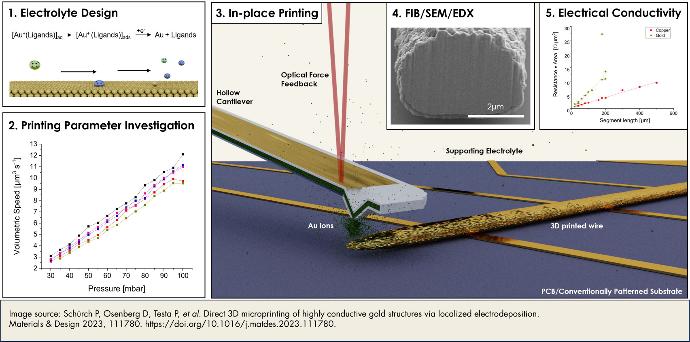

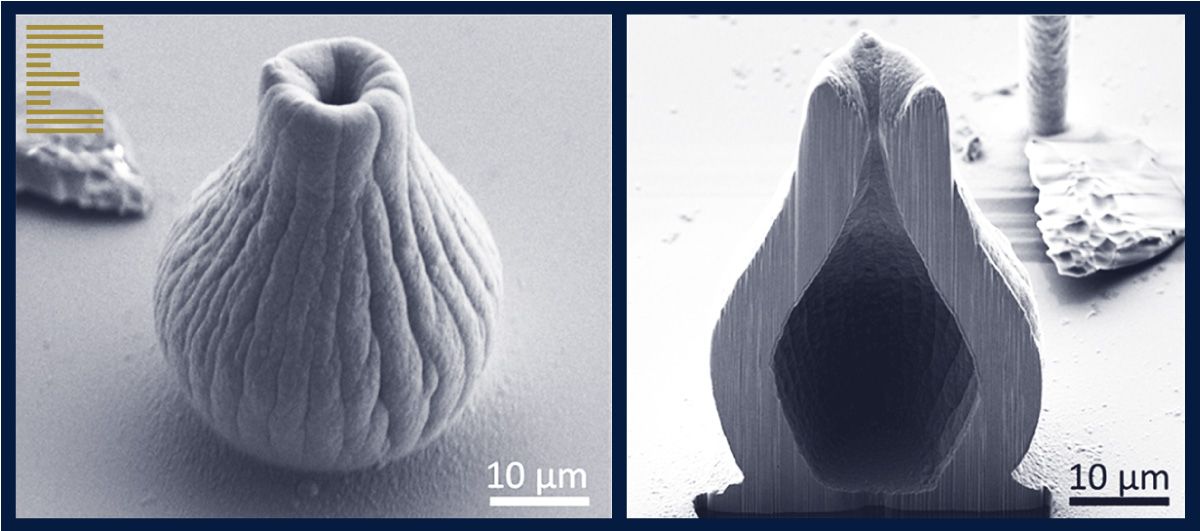

Microscale 3D Printing of Gold - New Exaddon and EMPA Research Published in Materials & Design

New collaborative research from Exaddon and EMPA, published in Materials and Design, details how highly conductive gold structures can be 3D microprinted directly on pre-patterned microchips via localized electrodeposition.

The test values are a significant step beyond existing methods used to microfabricate gold structures, and point toward superior functionality and device performance through use of locally electrodeposited gold.

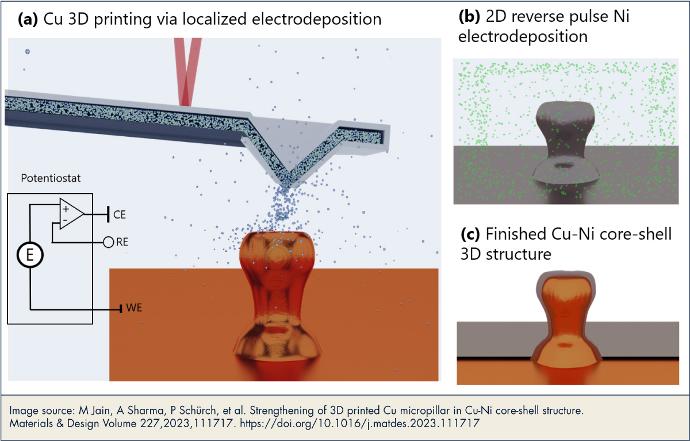

Strengthening of 3D Printed Copper Micropillars with Nickel - Exaddon & EMPA Joint Research

A new paper published in Materials and Design is the product of a combined research endeavor between Exaddon and EMPA, the Swiss federal laboratories for materials science and technology.

The study found an exceptional 3 fold increase in strength after coating the Cu microstructures with a Ni shell just 250 nm thick (compared to pure Cu).

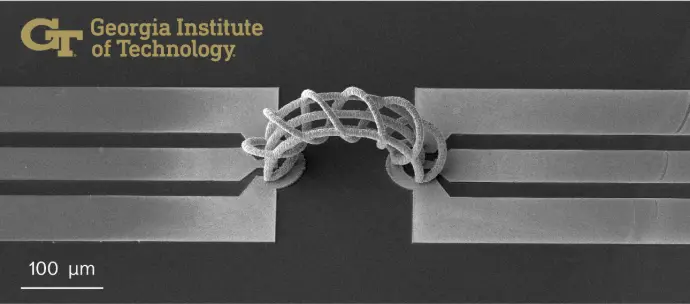

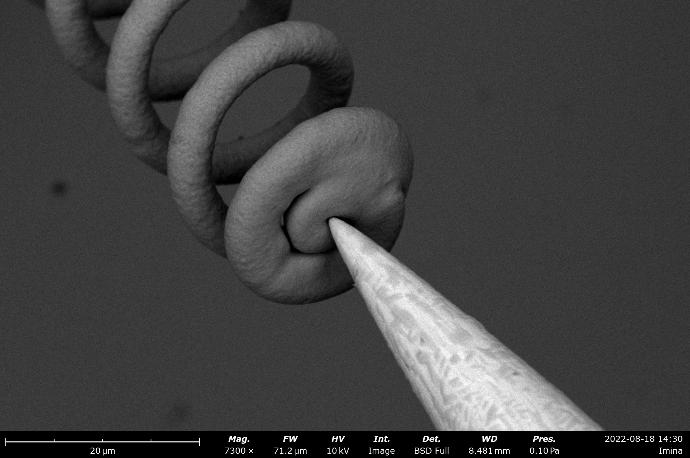

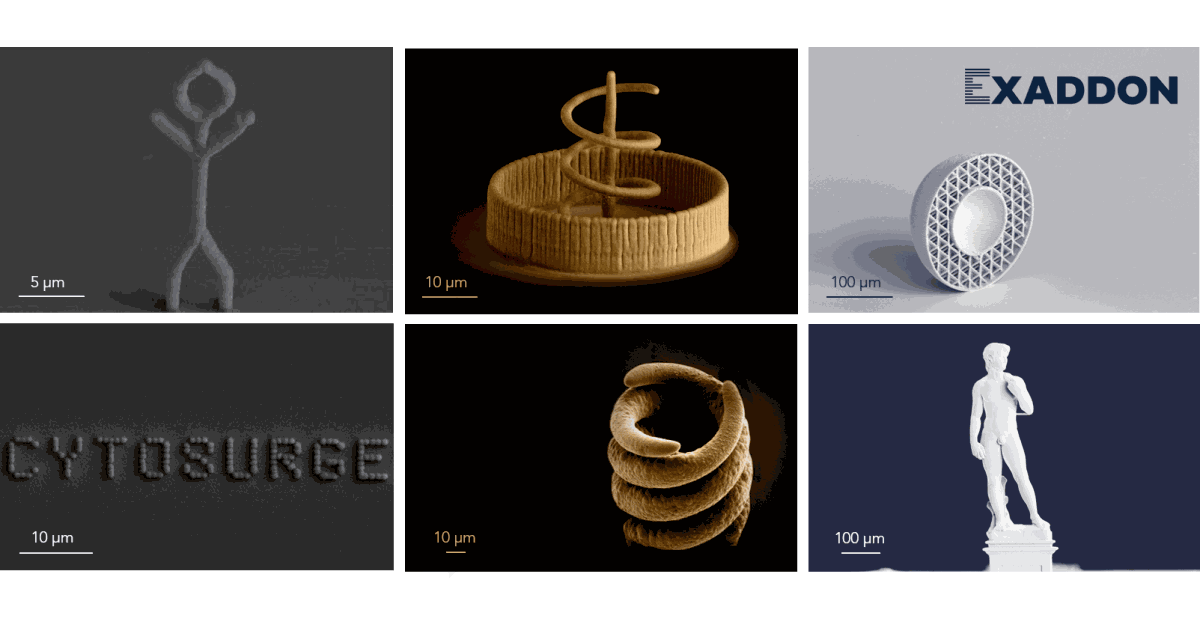

High Precision Collaboration Demonstrates Manipulation of 3D Printed Microsprings

Exaddon, Imina Technologies, and ThermoFisher Scientific joined forces to create fascinating images demonstrating the exact manipulation of microscale metal springs.

3D printed by Exaddon and imaged using a Thermo fisher desktop SEM, the springs were subject to precise mechanical manipulation by a robotic prober from Imina Technologies.

Additive Micromanufacturing in 2022 - Exaddon's Year Review

What were the key developments in the world of additive micromanufacturing (μAM) in 2022?

From system sales in 3 continents to new research published in high-level journals, new team members to new distribution partners, last year was one of progress and expansion on all fronts. Read below to see what the biggest news and advances were for Exaddon in 2022.

Exaddon Research Partner Awarded ERC Starting Grant for MEMS Research

Dr. Rajaprakash Ramachandramoorthy has been awarded a €1.5m European Research Council (ERC) starting grant for research into fabricating and testing 3D metal microarchitectures with additive micromanufacturing (µAM).

Dr. Ramachandramoorthy and his team at

Max-Planck-Institut für Eisenforschung

will be using their CERES system for microelectromechanical systems (MEMS) applications.

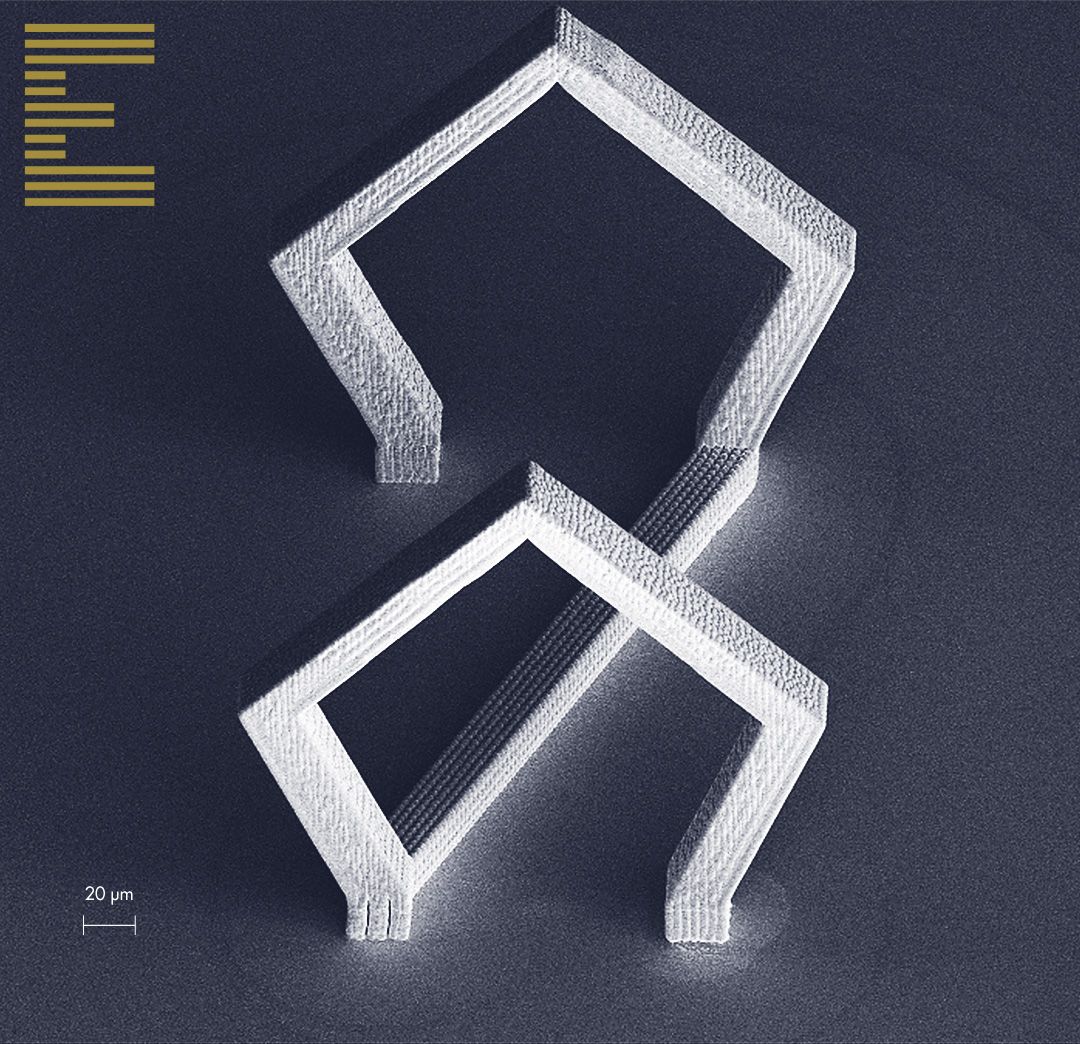

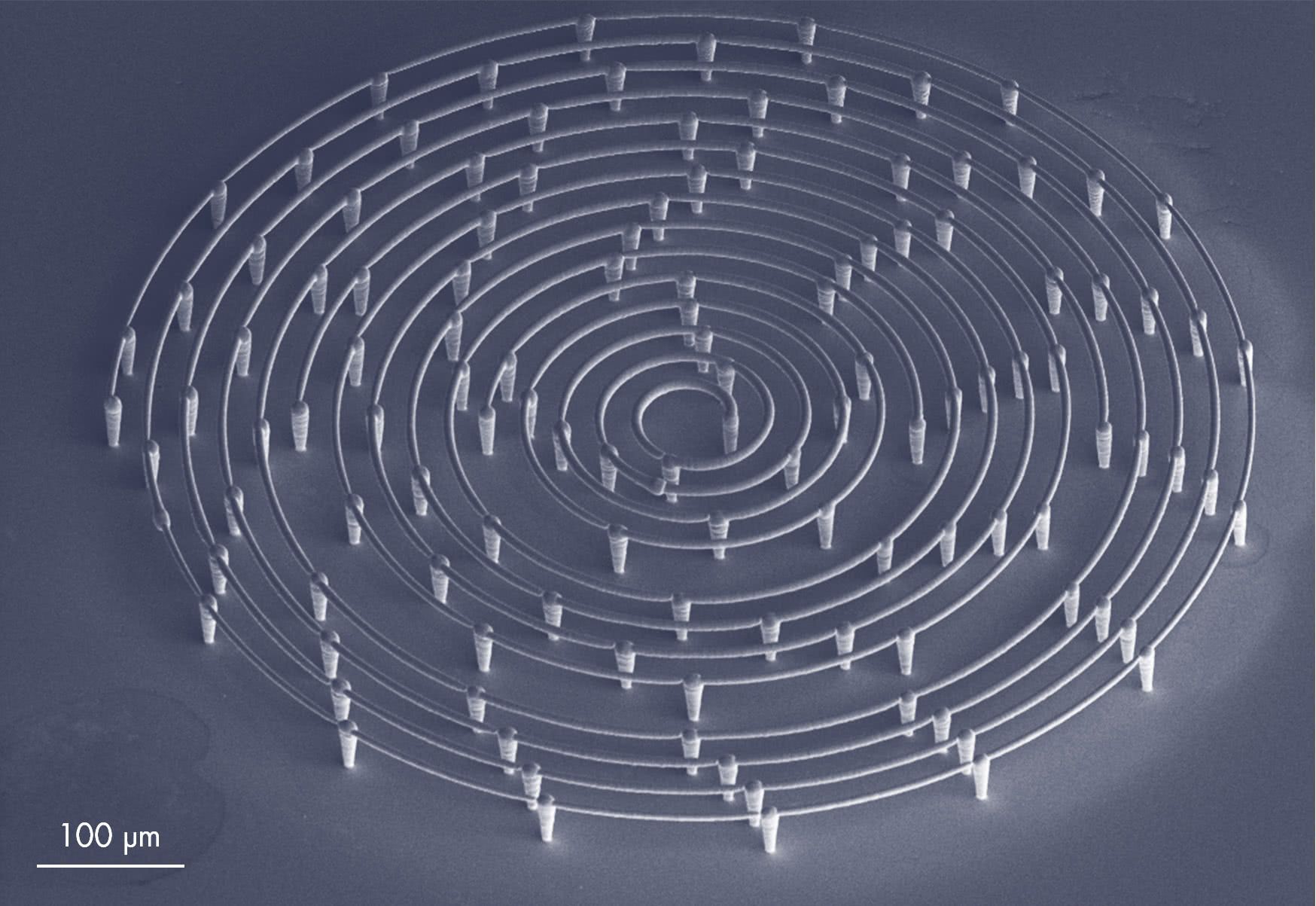

New IEEE Paper Demonstrates use of Additive Micromanufacturing for Microscale mmWave Structures

A paper from Goethe University, published in IEEE Transactions on Electron Devices demonstrates how Exaddon’s additive micromanufacturing (μAM) technology was used to fabricate microscale helices for use in mmWave components - a key development for 5G networks.

Purdue University Purchase CERES System for Neuroscience Research

Purdue University, USA have purchased a CERES µAM Print System to conduct pioneering research into the 3D printing of neural implants for use in neuroscience applications.

The CERES system has been installed at the Nano Neurotechnology Lab, headed by Professor Krishna Jayant.

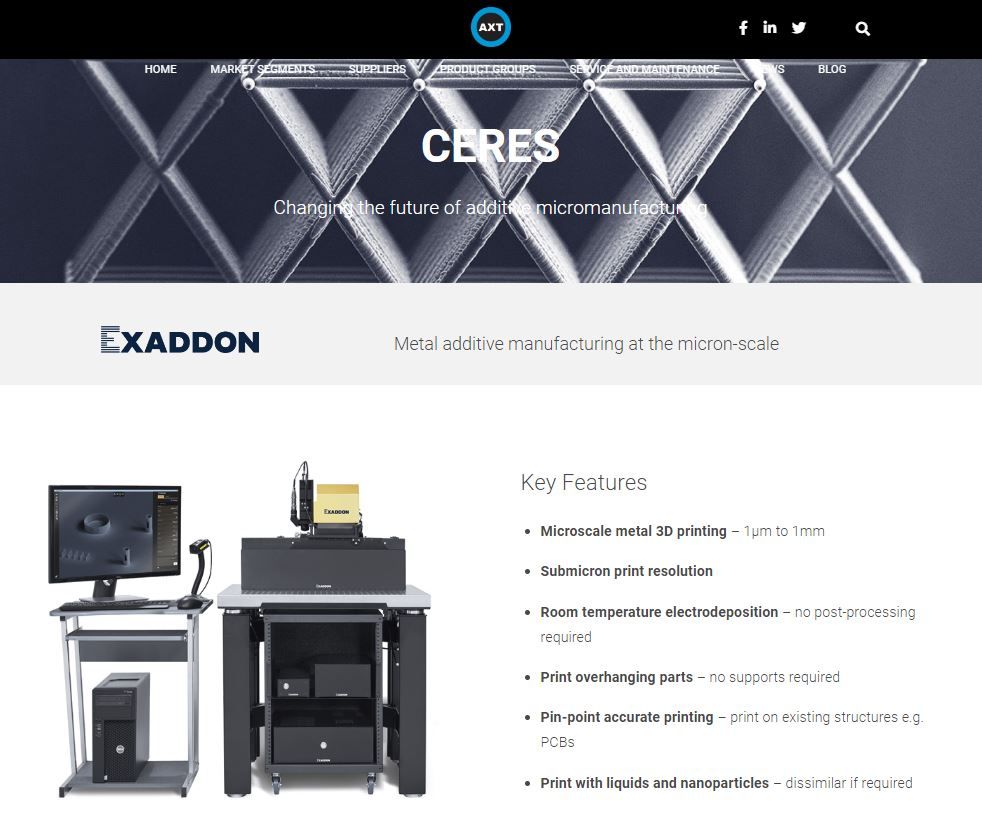

Exaddon Partners with AXT for Microscale Additive Manufacturing Distribution in Australia & New Zealand

We're excited to announce that Exaddon's unique metal µAM (additive micromanufacturing) technology is now distributed in Australia and New Zealand by scientific instrumentation experts AXT.

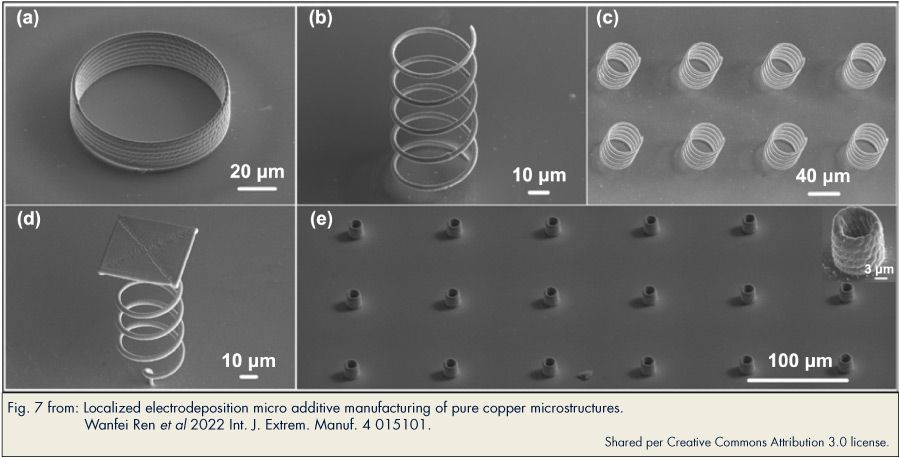

International Journal of Extreme Manufacturing - New Research Features Exaddon μAM Technology

A Chinese research collaboration between members of Jilin University and Changchun University of Science and Technology (CUST) describes their use of localized electrochemical deposition (using the Exaddon CERES system) to additively manufacture microscale copper structures.

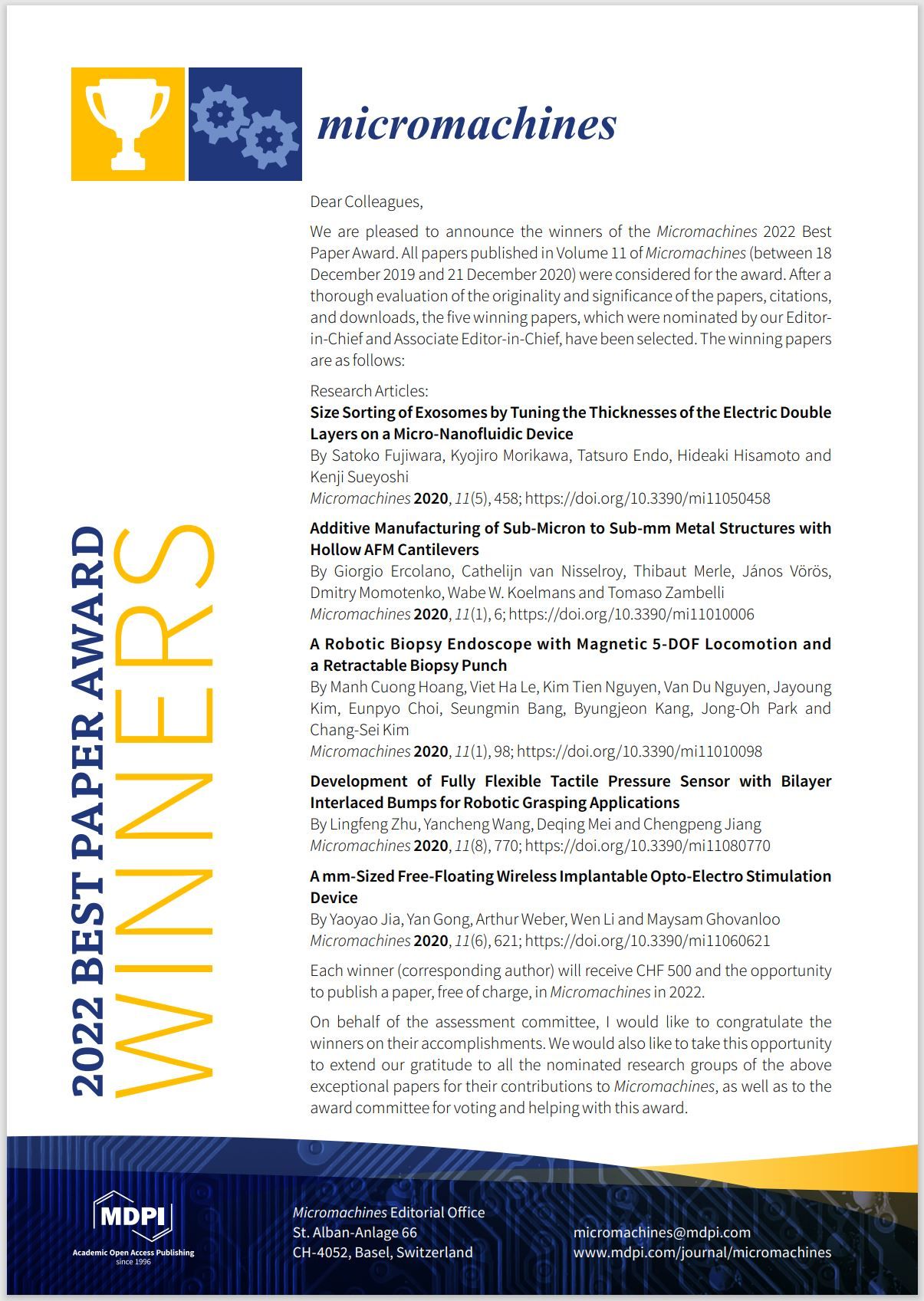

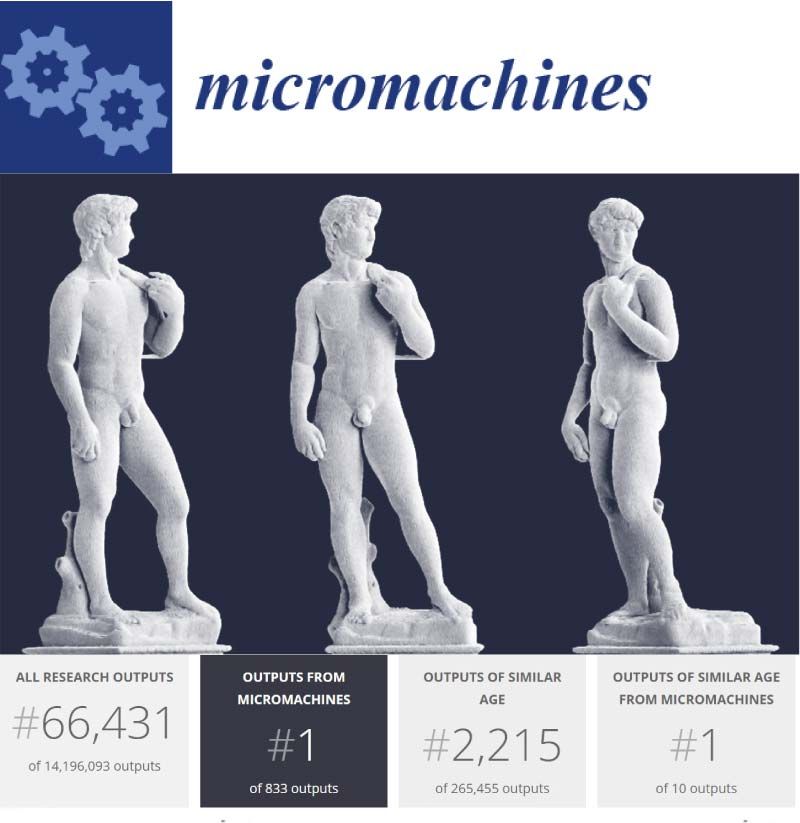

Exaddon Research Wins 2022 Micromachines Best Paper Award

Exaddon research has been recognized in the

Micromachines

2022 Best Paper Awards. The paper, entitled "Additive Manufacturing of Sub-Micron to Sub-mm Metal Structures with Hollow AFM Cantilevers", describes Exaddon's force-controlled 3D printing method for layer-by-layer additive micromanufacturing (µAM) of metal microstructures.

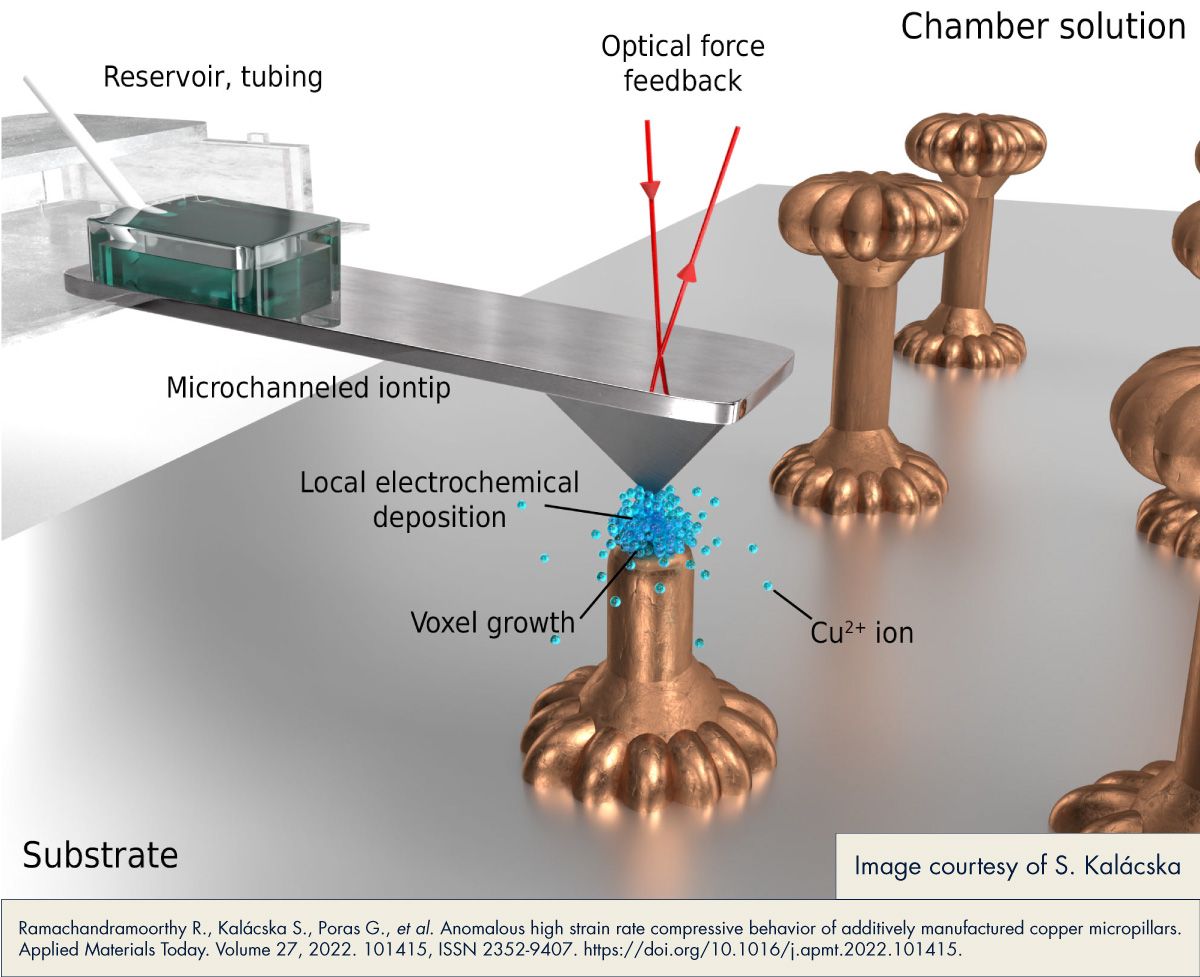

Exaddon Research in Applied Materials Today - Microstructural Characterization of Micropillars

A research collaboration between Exaddon, EMPA, and Max-Planck-Institut für Eisenforschung (MPIE) has resulted in novel research into the dynamic strain properties of 3D printed copper micropillars.

The paper, published in Advanced Materials Today, describes how the pristine structures behaved when subject to a wide range of crush speeds, from low to very high strain rates.

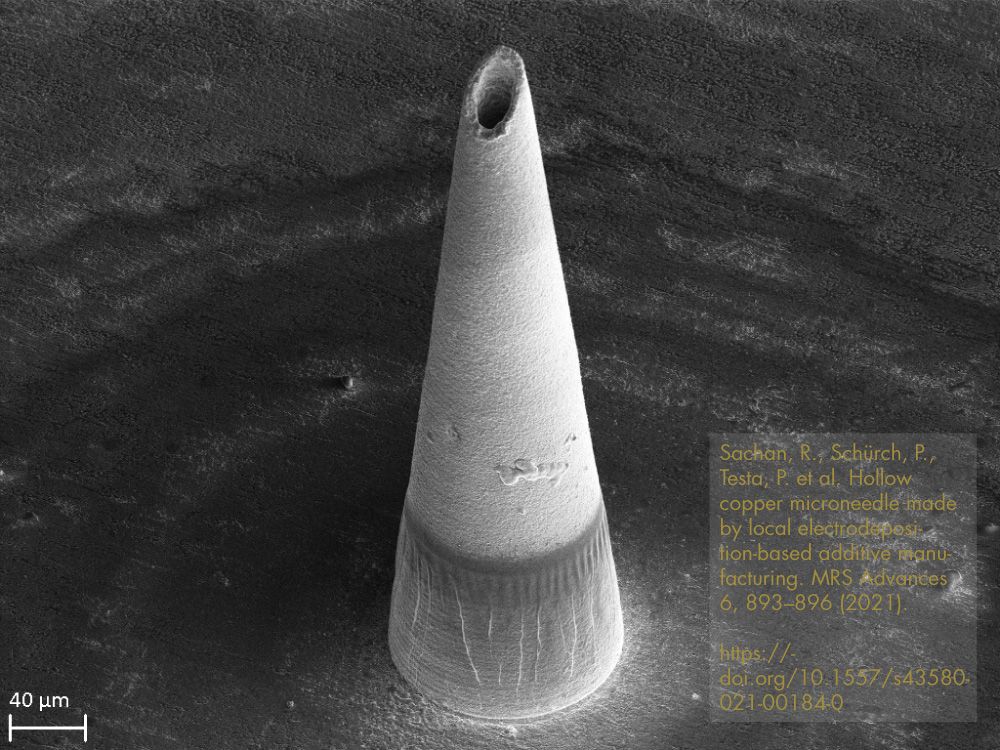

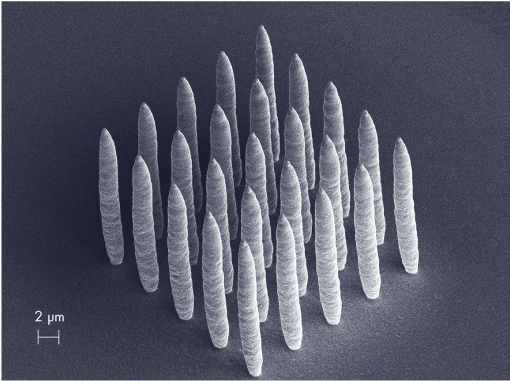

Exaddon Research in MRS Advances - 3D Printed Copper Microneedles for Drug Delivery

In a research collaboration between Exaddon, North Carolina State University State University and the University of North Carolina at Chapel Hill, hollow microneedles were created out of copper.

Published in MRS Advances, the study demonstrates the potential use of Exaddon's pioneering metal additive micromanufacturing (µAM) technology to manufacture hollow copper needles for drug delivery.

Max-Planck-Institut für Eisenforschung Purchase CERES System

The Department of Structure and Nano- / Micromechanics of Materials at MPIE now own a CERES system to advance their research in various exciting projects in fluid mechanics and materials science.

Group Leader Rajaprakash Ramachandramoorthy and the team will be using the CERES system for investigations in multiple fields.

University of Oregon Purchase CERES System for Research into Microscale Additive Manufacturing

The University of Oregon’s Technical Sciences Administration center is now home to the first CERES µAM print system in the USA!

Headed by John Boosinger, the 3D Printing Lab will utilize CERES for a variety of tasks both within the University and to external affiliates. This is a great step forward in bringing Exaddon's pioneering technology to a wider audience.

New CERES System Delivery and Installation in FBH Berlin!

We are delighted to announce the delivery and installation of another our CERES µAM print systems, this time to the renowned Ferdinand-Braun-Institut, Leibniz-Institut für Höchstfrequenztechnik!

The CERES system takes its place within FBH’s brand new 1000 m2 cleanroom dedicated to III-V electronics and optoelectronics research.

Exaddon Exhibit & Present at Micro- Nano Engineering Conference 2021, Torino

The 47th Micro and Nano Engineering Conference in Torino (September 20-23) saw Exaddon exhibiting in the expo area throughout the event, as well as presenting in the speaker presentations.

Exaddon electrochemist Dr Patrik Schürch presented new findings around our gold 3D printing capabilities in his talk "On-chip microscale 3D printing of gold via locally confined electrodeposition".

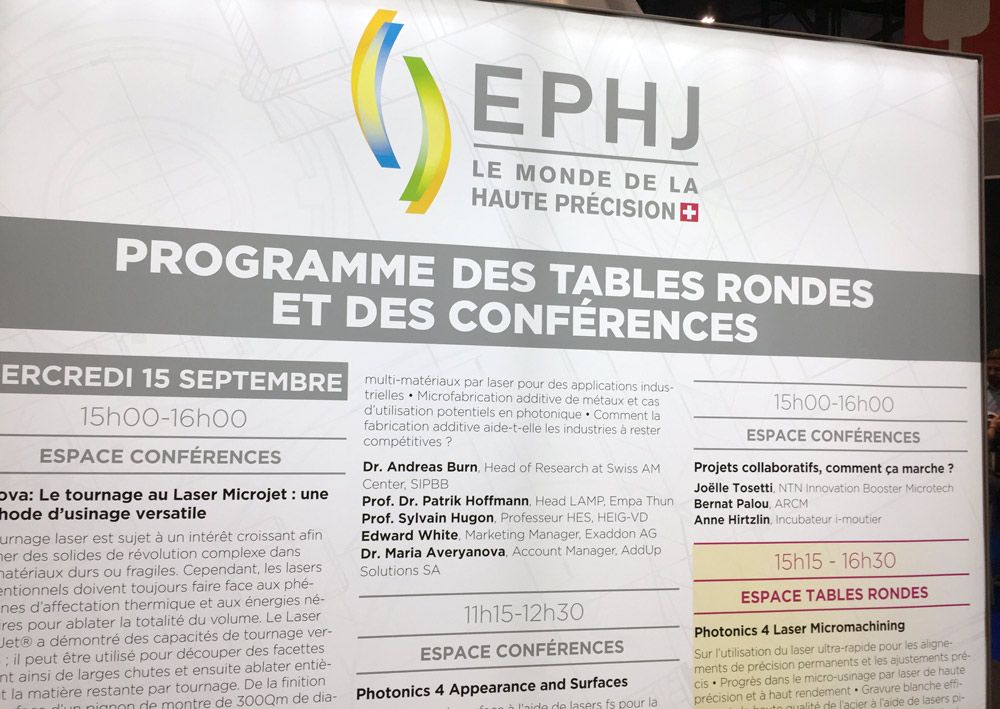

Exaddon Present at Swiss Photonics Conference, EPHJ 2021

EPHJ is the leading Swiss exhibition of watchmaking, MedTech, and high precision. This year, it was accompanied by a meeting of the Swiss Photonics conference series.

Exaddon presented potential use cases of the CERES system for photonics applications, as part of the Photonics 4 Additive Manufacturing session.

Exaddon and matériO Display at the Maison&Objet Fair in Paris

Early in September, the matériO display at the renowned Maison&Objet fair featured a special guest, notably a 1000 µm tall replica of Michelangelo's David, 3D printed in pure copper.

The innovative matériO display was one of 300 exhibits on show to over 48,000 guests.

Exaddon Featured in 'Best Micro 3D Printers 2021'

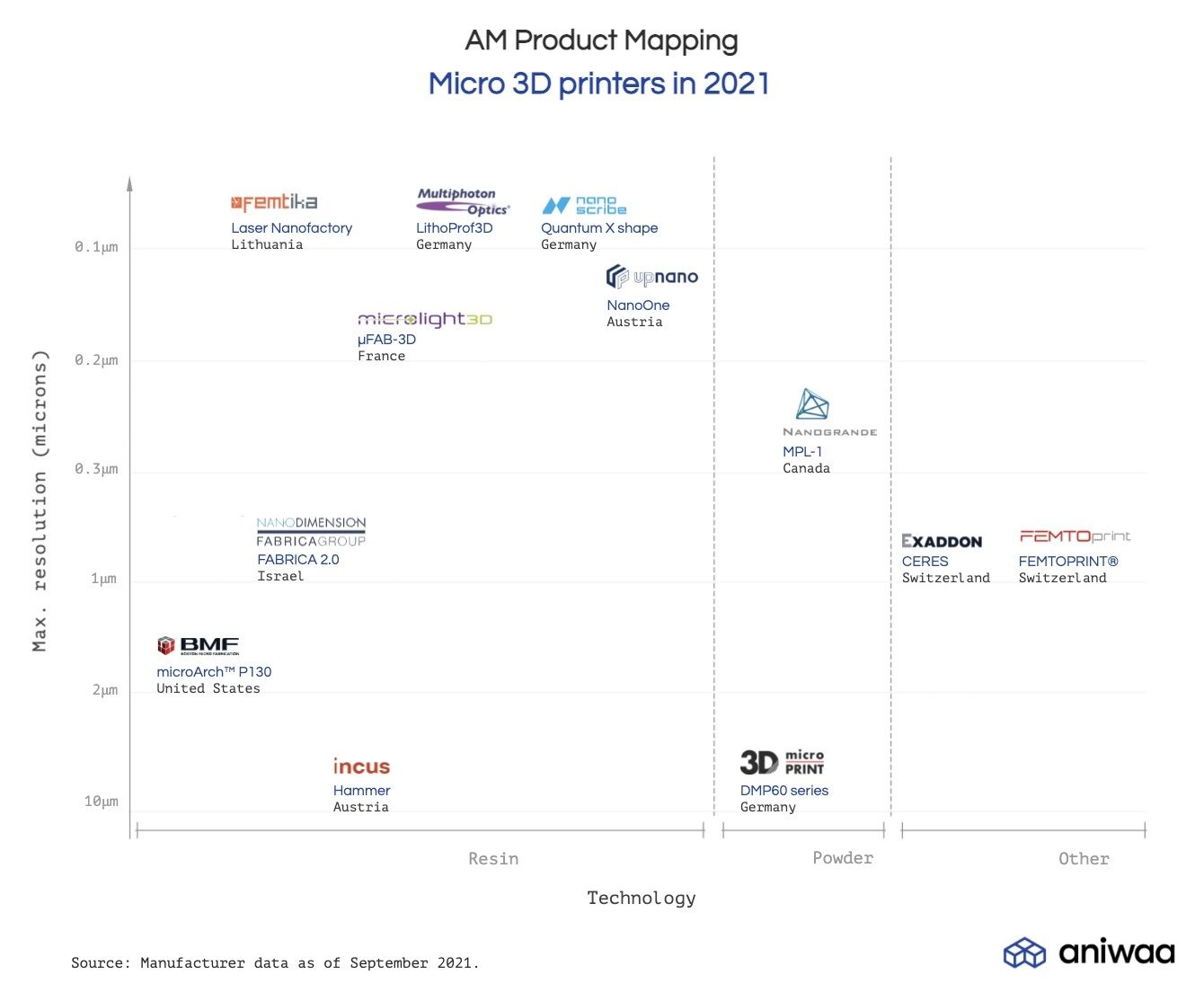

3D Printing Technology Resource and Database website Aniwaa.com recently conducted an overview of select microscale AM companies, and Exaddon was one of 12 featured.

Q & A: Part Two - 3D Metal Printing at the Microscale

Part two of our Q & A series covers print speed, electrochemistry, and comparison with two-photon polymerization (2PP).

Q & A: Part One - 3D Metal Printing at the Microscale

Part one of our Q & A series covers which print materials and substrates are possible with the CERES print system, as well as the material properties of printed objects.

High Strain Rate Testing of Microscale Metal Objects 3D Printed with the Exaddon CERES System

Get a glimpse into a research collaboration between Exaddon, EMPA, and Max-Planck Institute which investigates behavior of microscale copper objects produced by additive micromanufacturing.

We share the abstract of Professor Rajaprakash Ramachandramoorthy's MRS presentation:

High Strain Rate Testing from Micro-to-Meso Scale.

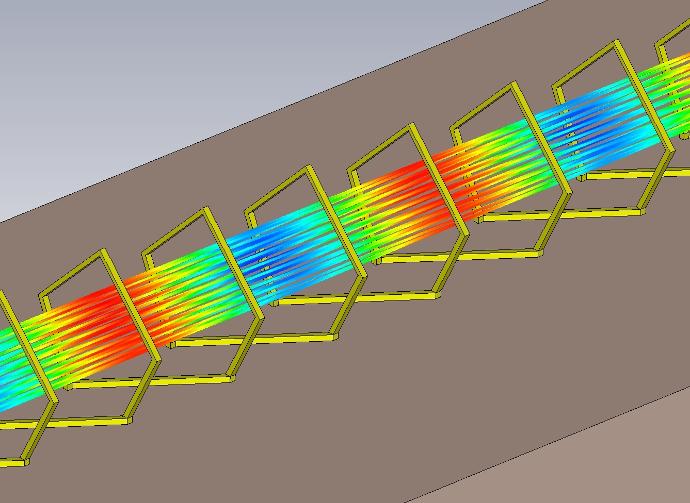

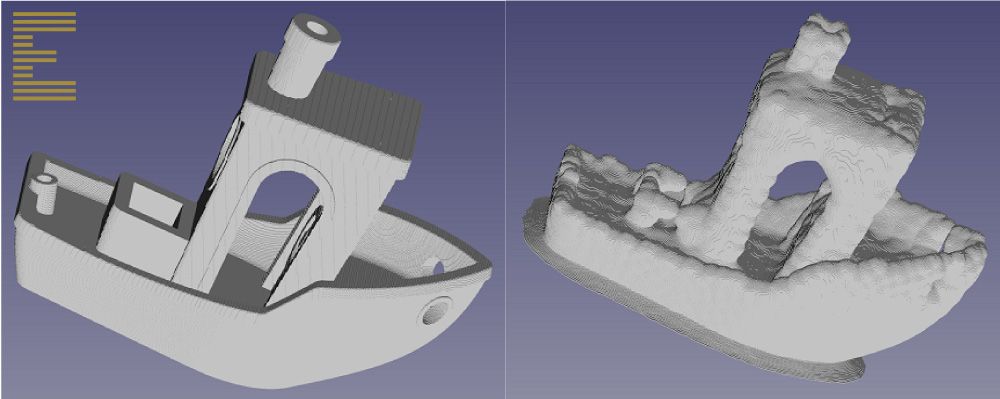

Developing a µAM Simulator

What will an object look like when it has been printed with µAM, and what degree of tolerance can a user expect?

Our engineers have been busy developing a simulation which answers those questions, and even the first experimental versions are impressive.

University of Pisa purchase CERES µAM print system

Professor Giuseppe Barillaro and his team at the University of Pisa will further their research endeavors with the unique capabilities of microscale metal AM.

Acquired through the framework of the Center for Instrument Sharing University of Pisa (CISUP), the CERES printer will see use by a whole wide range of different research departments.

Achieving 5G and Beyond with Microscale Additive Manufacturing

How to reach 5G and beyond with microscale additive manufacturing?

Achieving an ultra-capacity layer capable of 100 gigabits of data per second is a complex problem requiring a truly innovative solution.

Exaddon collaborated with Professor Viktor Krozer and his team at Goethe University to develop µAM components for 5G usage.

Changchun University purchase CERES µAM print system

The Changchun University Science and Technology team purchased the CERES system and carried out the first µAM print in China.

The team will be researching the interaction of water droplets with functional surfaces of metal microstructures.

Neuroprosthetics and Additive Micromanufacturing

Brain-machine interfaces are rapidly gathering momentum as potentially revolutionary devices with the ability to change lives.

Our CERES µAM print system is well-suited to printing the complex and tiny structures necessary for conductive, mechanically stable electrodes in BMI applications.

Material Properties of Printed Objects

Learn more about the material properties and grain structure of objects printed in pure copper with our CERES µAM print system.

We cover conductivity, elasticity, grain structure, and substrate adhesion.

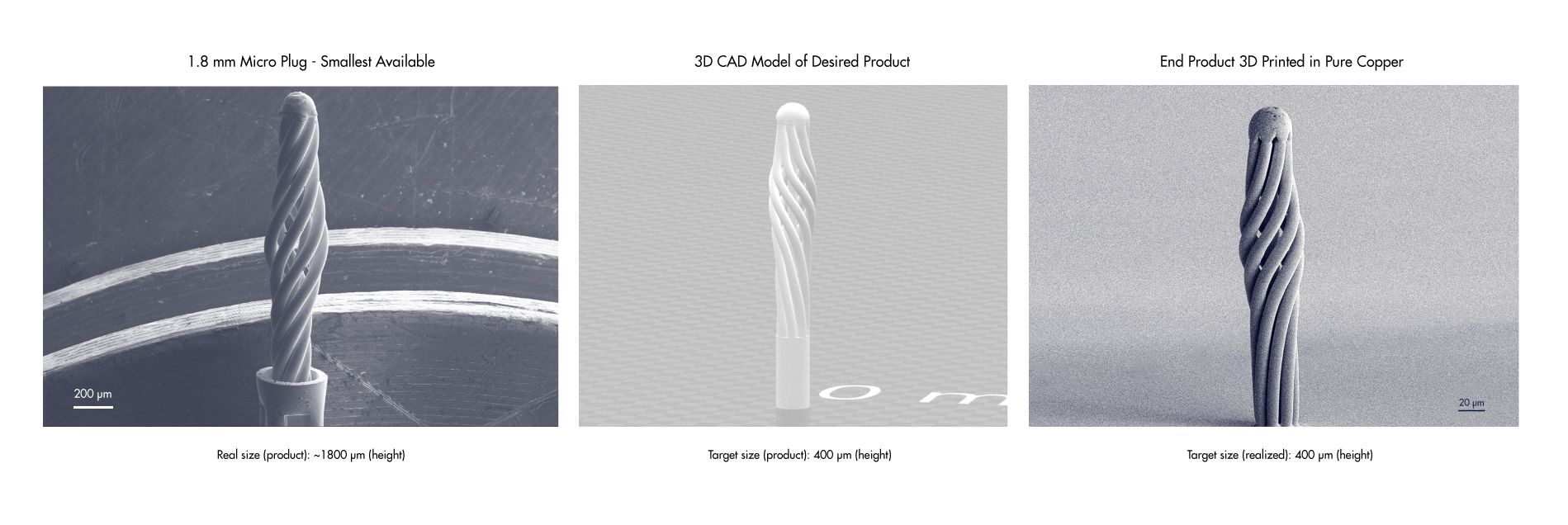

Exaddon + Axon' Cable - Redefining Microconnectors & Changing Lives

Using our unique µAM print technology, Exaddon was able to produce microplugs for Axon' Cable just 400 µm long, enabling Axon' to manufacture medical interconnects which will help transform patients' lives.

Read the full press release about our cutting-edge collaboration with Axon' Cable.

µAM Competitive Landscape Overview

Most industry overviews in the additive manufacturing media focus on companies able to 3D print large objects at large scale. Exaddon's one-of-a-kind technology puts it in a unique position in the micro AM space. We take an overview of the competitive landscape, focusing on materials, object size, and potential use cases.

Micromachines Paper Goes Global

Christmas 2019 saw our Micromachines research paper go global, thanks to coverage by TechCrunch, Forbes, CNET, and more.

After just one month, it ranks in the top 5% of all 14m+ research outputs calculated by Altmetric - proof indeed that our unique µAM technology is breaking new ground.

Exaddon - 2019 Year in Review

2019 was a very busy year for the additive manufacturing industry, and especially for Exaddon. Read more about the development of the additive micromanufacturing industry, our research collaborations, and publications.

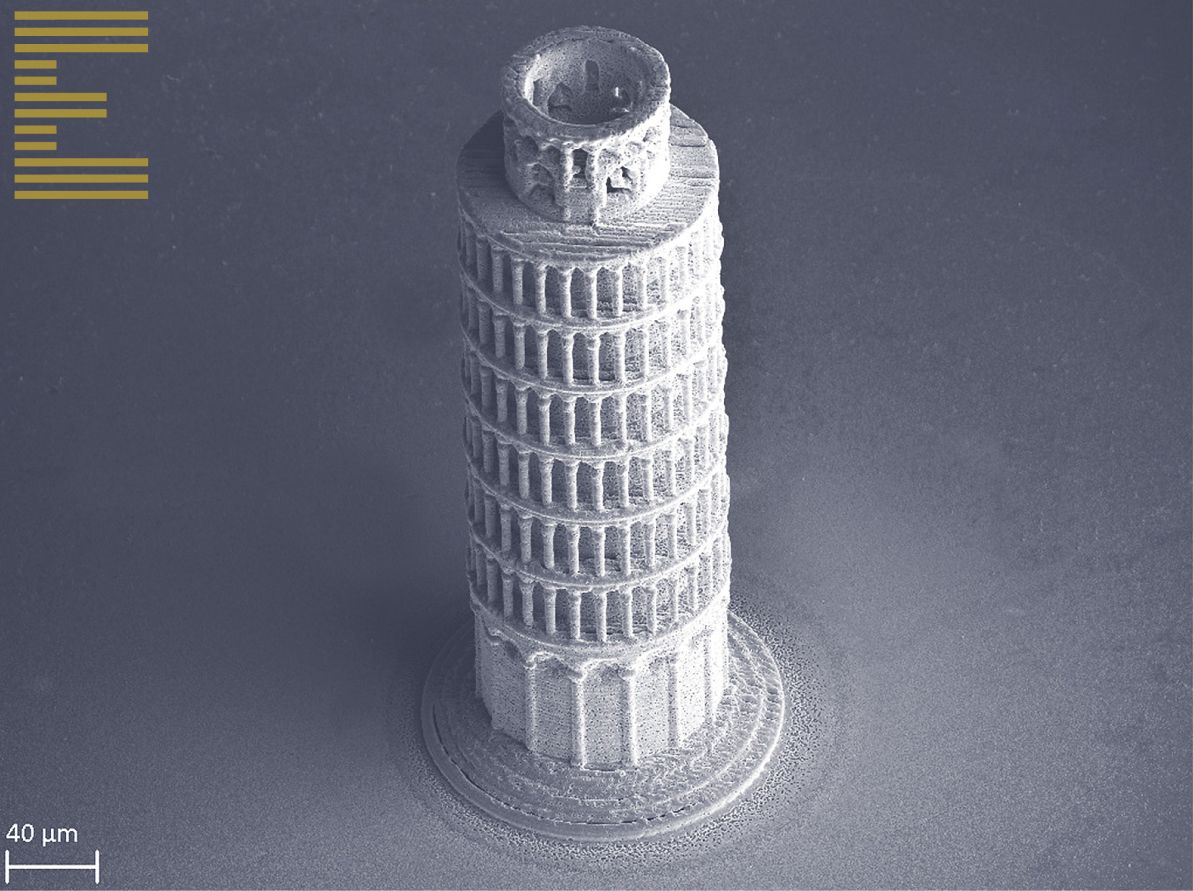

A metal version of Michelangelo’s David made in microscale by additive manufacturing

Thanks to significant advances in the development of the CERES additive micro-manufacturing system, Michelangelo’s David exists now in the size of a little ant.

Exaddon AG - 3D Printing company founded

The 3D printing business unit of Cytosurge AG has been spun-off into a new autonomous company, Exaddon AG, focusing on the development of processes and systems in the field of additive manufacturing of microscopically small metal components.