Exaddon customer Georgia Tech Institute for Matter and Systems has published dramatic new research demonstrating fabrication of high frequency components using Exaddon’s micro3D printing technology. The first-of-its-kind microscale interconnect design was extremely complex, showing off the template-free capabilities of the CERES system.

High Speed Wireless Communication is Facing a Challenge

The global demand for high-speed, reliable broadband data links has resulted in many developments in mmWave technologies, yet the fabrication of low-loss interconnects remains an unsolved challenge.

Put simply, interconnects are tiny electrical components necessary for the propagation of signals between the various parts of a network, such as transmitters or receivers. In high-speed wireless communication networks, it is very important for these interconnects to be shielded from electromagnetic interference, which can cause data loss or corruption.

Until now, the preferred method of interconnect fabrication among integrated circuits (ICs) has been wire bonding, thanks to its ease of implementation and cost effectiveness. However, signal losses beyond 100 GHz are common to wirebonded interconnects, and for the increasing demands placed upon wireless data links, this is inadequate.

A Solution through Innovation - Exaddon micro3D Printing

To enable the next generation of ultra broadband networks, low-loss interconnects capable of operating beyond 100 GHz are needed.

This requires a manufacturing method which offers incredible precision, object resolution, and design freedom. For conventional manufacturing methods, the required interconnect dimensions are simply too small, and the required designs too complex.

The Exaddon CERES print system offers all of these capabilities, and the unique benefits of its template-free electrodeposition have already been proven in mmWave research by other universities.

A First of Its Kind Shielded Interconnect Design

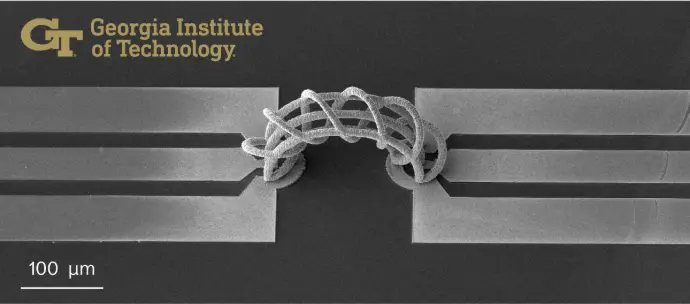

Georgia Tech used the Exaddon CERES print system to create a first-of-its-kind shielded interconnect design in geometries unachievable by other fabrication methods. The interconnects were printed in copper, with the outer wire conductor measuring just 12 µm in diameter.

The helical shield was design to minimize RF transmission losses, compared to conventional wirebond interconnects. According to the paper, this shielded interconnect design

"resembles the ideal transmission performance of a microscale coaxial cable, significantly reducing the impedance mismatch losses that are typically observed in conventional wirebonding interconnects when utilized beyond 100 GHz. The measurements demonstrate superior and reliable performance at least up to 155 GHz."

Paving the Way for Next-Generation Solutions

The key takeaway of the paper is powerful:

"The proposed μAM-enabled interconnect has the potential to pave the way for the next generation of heterogeneous packaging solutions targeted for sub-terahertz (THz) applications that require robust and broadband performance."

Georgia Tech's research is further proof of the unique possibilities which our technology opens in the field of high-frequency applications.

Access the paper in IEEE Microwave and Wireless Technology Letters here.

Reference:

G. Soto-Valle et al., "Novel Low-Loss Shielded Interconnects for D-Band/Sub-THz Applications Using Microscale Metal Printing Technologies," in IEEE Microwave and Wireless Technology Letters, vol. 35, no. 6, pp. 776-779, June 2025, doi: 10.1109/LMWT.2025.3552351.

Georgia Tech Publishes Breakthrough Sub-THz Research with Exaddon micro3D Print Technology