Exaddon micropillars give unprecedented yield strength results

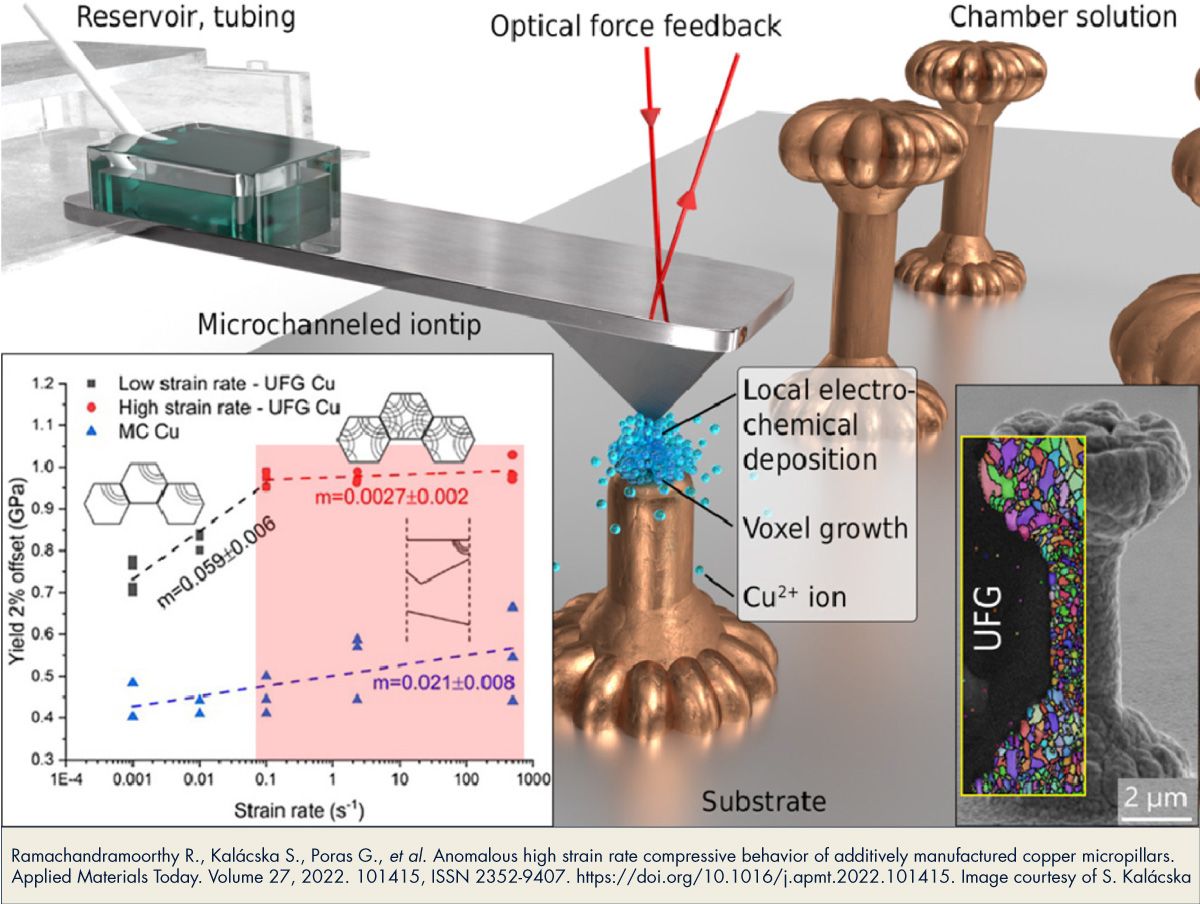

A new study reveals that pristine copper micropillars produced by Exaddon’s CERES µAM print system exhibited unprecedented yield strength when subjected to a range of crush speeds.

A research collaboration between Exaddon, EMPA, and Max-Planck-Institut für Eisenforschung (MPIE) has resulted in novel research into the dynamic strain properties of 3D printed copper micropillars.

The paper, published in Applied Materials Today, describes how the pristine structures behaved when subject to a wide range of crush speeds, from low to very high strain rates. The strength measurements showed very high yield strength of the µAM copper over all speeds.

Notably, the 2 µm diameter pillars were pristine, meaning that they hadn’t been obtained by FIB cutting. This is an important point, as results of some tests can be influenced by the measurement method itself. However, lead author Rajaprakash Ramachandramoorthy and his team carried out their rigorous investigations in a way which ensured that the results show the true behaviour of the micropillars.

Further, the team assessed the grain structure of the microprinted metal pillars, and investigated how the grain size influenced the pillar behavior when subjected to mechanical stress.

Key Findings

The study shows an unprecedented yield strength across certain strain rates. Specifically, the yield strength ranged from 0.4 up to 1.0 GPa (see Fig. 6 in the paper here).

This is the highest strain-rate dependent yield-strength in literature - not only additive manufacturing literature.

Now that the yield strength and mechanical behavior of µAM copper is known, this information can be used to build bigger, more complicated microscale AM structures; paving the way for subsequent investigation in this novel and innovative area.

Browse further Exaddon publications.

Full paper available here: https://doi.org/10.1016/j.apmt.2022.101415.

Ramachandramoorthy R., Kalácska S., Poras G., et al. Anomalous high strain rate compressive behavior of additively manufactured copper micropillars. Applied Materials Today. Volume 27, 2022. 101415, ISSN 2352-9407.

Discover material properties of printed objects

Read the latest figures and test results for Exaddon printed objects

Exaddon Research in Applied Materials Today 2022 (27) - Microstructural Characterization of Micropillars