3D Printing Neural Interfaces with Exaddon µAM

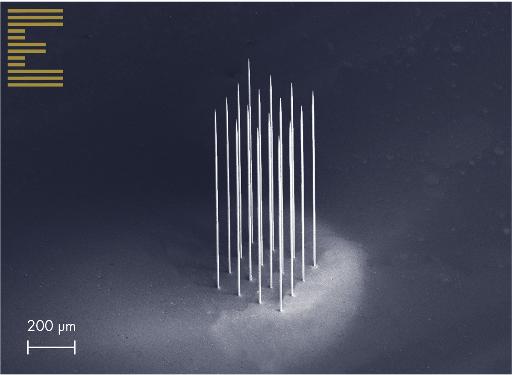

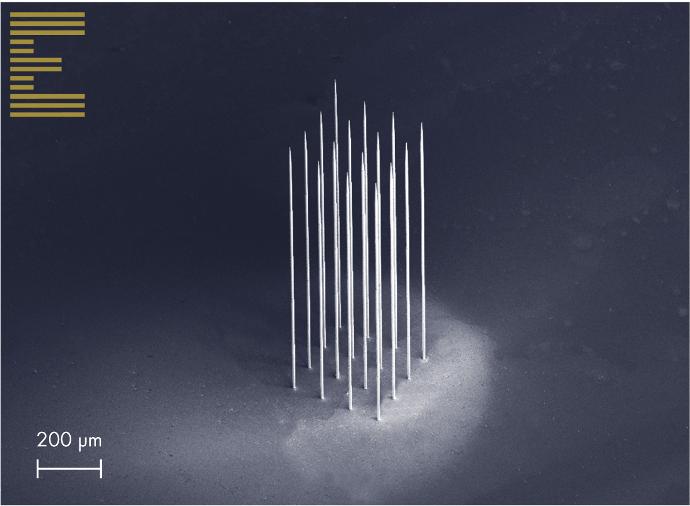

High Aspect Ratio

Print high aspect ratio (100:1) structures directly on prepatterned traces or contact pads with micrometer accuracy.

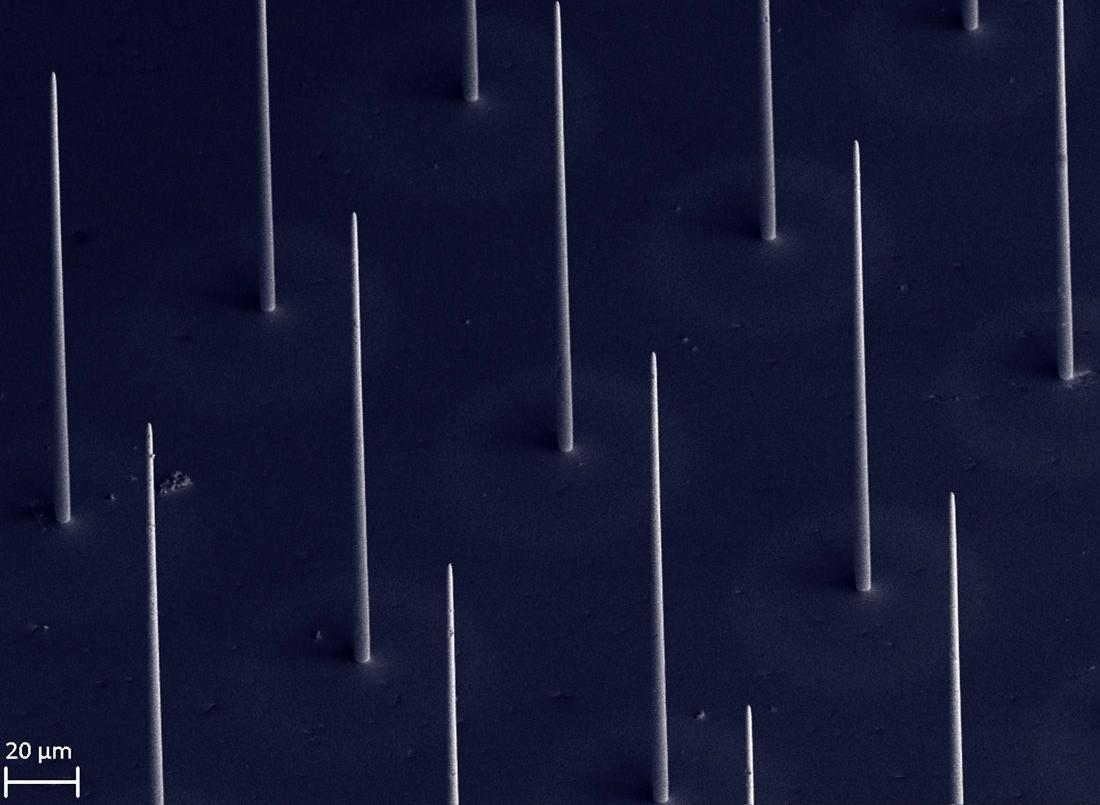

Cu or Au Micropillars

High conductivity pure metal needles and pillars, printed at room temperature with local electrodeposition. Pillars can be coated after printing.

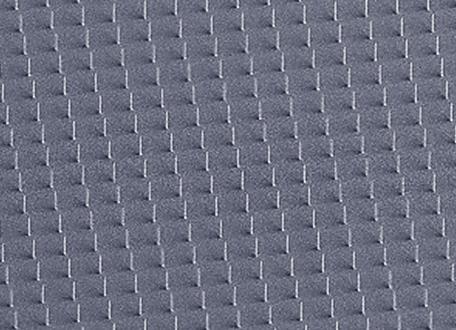

Fine Pitch Arrays

Pitch can be customized as needed. Image: 40 x 40 array of 1.6 μm diameter Cu pillars, printed at 25 μm pitch. 1600 pillars total.

An emerging discipline

combining neuroscience and biomedical engineering, neuroprosthetics (often referred to as brain-machine or

brain-computer

interfaces, neural interfaces, or cortical implants) involves connecting external computing power to the brain via electrodes or implants in order to assist or replace human brain functionality, or simply to monitor brain activity.

Through the placement of an electrode sensor on the brain, these brain-machine interfaces enable functions which are no longer possible by the human body.

An increasing number of highly innovative companies are improving the lives of people suffering from hugely disempowering conditions such as Parkinson's or Alzheimer's, through use of implantable devices which are linked to external computers.

An increasing number of highly innovative companies are improving the lives of people suffering from hugely disempowering conditions such as Parkinson's or Alzheimer's, through use of implantable devices which are linked to external computers.

Manufacturing tiny electrodes

for implant into the brain is extremely challenging for conventional

technologies, but it is where Exaddon's 3D printing excels.

The CERES system can 3D print electrode arrays in geometries impossible for other technologies, making it a unique solution for teams researching neural interfaces and electrodes.

The incredibly precise electrochemical deposition results in high conductivity metal which is inherently biocompatible (Au).

Micropillars can be printed with diameters as small as ~1 µm, and in arrays with customizable pitch.

CERES µAM print system is perfectly suited to creating conductive, mechanically stable electrodes.

CERES µAM print system is perfectly suited to creating conductive, mechanically stable electrodes.

Explore more microscale 3D printing use cases: High Frequency Technology

3D Print Waveguides and Antennas for High Frequency Applications