3D Printed Metal Microneedles for Drug Delivery

Creating Transdermal Drug Delivery Microneedles with Micro3D Printing

Transdermal drug delivery is an increasingly important topic, especially since the attention which vaccines have received in recent years.

Long-lasting, slow-release drug delivery is preferred for treatment of certain illnesses and diseases, and this can be addressed through use of transdermal microneedle arrays, as opposed to conventional single-site needles. Benefits include:

- Microscale sizes

- Painless

- No bleeding

- Low doses

- Small patch sizes

However, use of microneedles brings manufacturing challenges:

- Needles need to be long enough to penetrate undulations in the skin at a micron level.

- Entire needle aperture needs to be below the stratum corneum (the elastic outermost layer of the skin) in order for the drug to be delivered effectively.

- This requires high resolution manufacturing to create an accurate needle opening; if the opening isn't fully below the stratum corneum, the drug will disperse over the skin surface, and thus be ineffectual.

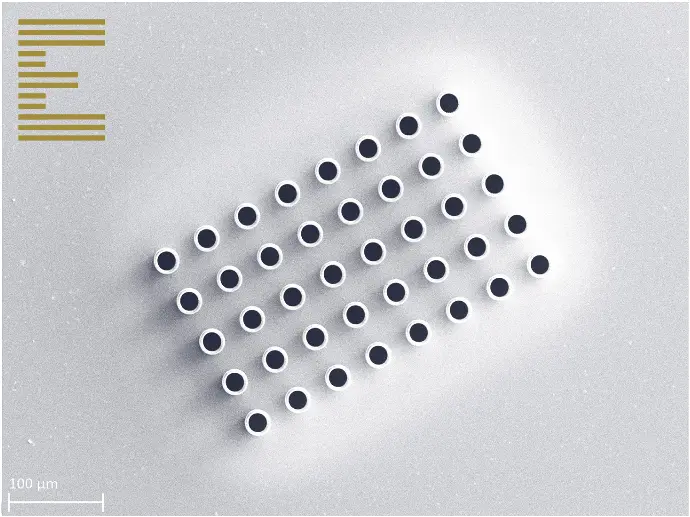

An array of metal microneedles printed in copper with the CERES system.

An array of metal microneedles printed in copper with the CERES system.

Printing Microneedles with Exaddon Technology - Published Research

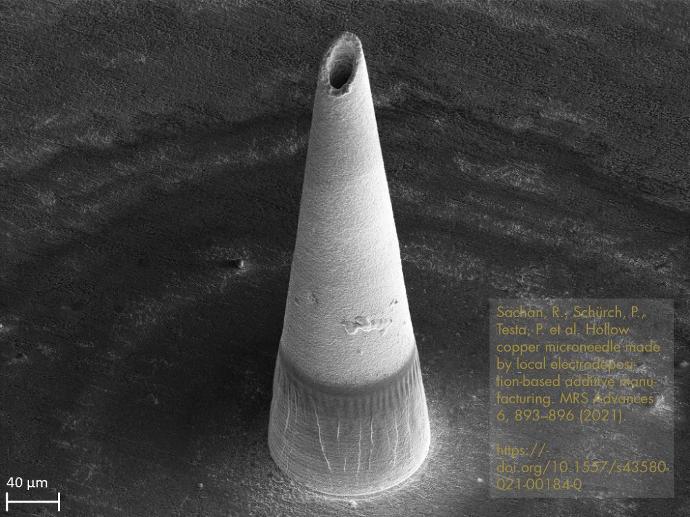

In a research collaboration between Exaddon, North Carolina State University State University and the University of North Carolina at Chapel Hill, hollow microneedles were created out of copper using Exaddon's local electrodeposition-based additive manufacturing process.

Published in Materials Research Society Advances, the study demonstrates the potential use of Exaddon's pioneering metal additive micromanufacturing (µAM) technology to manufacture hollow copper needles for drug delivery.

Exaddon's CERES Print System was used to print the needles, in this instance 431 µm in height. According to the paper, "x-ray photoelectron spectroscopy showed the presence of copper, oxygen, copper, silicon, and sulfur and the absence of toxic impurities in a solid microneedle."

Accordingly, the 3D printing of copper microneedles may be an appropriate method of manufacturing biocompatible structures suitable for transdermal drug delivery.

Paper reference: Sachan R., Schürch P., Testa P. et al. Hollow copper microneedle made by local electrodeposition-based additive manufacturing. MRS Advances 6, 893–896 (2021). Springer

Advantages of Exaddon 3D Printing over Two-Photon Polymerization (2PP)

Much research has already been conducted in this area using techniques such as two-photon polymerization (2PP), a method of additive manufacturing which produces polymer parts with high resolution.

However, for some uses 2PP has inherent shortcomings. For example, if parts are required to be conductive or high strength is required, the polymer structures must be coated with metal before the polymer core is removed via plasma etching.

This can be a time-consuming process, and adequate results not guaranteed. Printing directly in metal circumvents these additional processing steps, and delivers metal structures with excellent conductivity and tensile strength values.

This makes Exaddon's metal additive manufacturing ideal for creating microneedles for drug delivery; it delivers high resolution, micrometer scale objects with excellent material properties. As Prof. Roger Narayan and the joint team have proposed in their paper, microscale metal 3D printing could be a viable solution to 2PP.

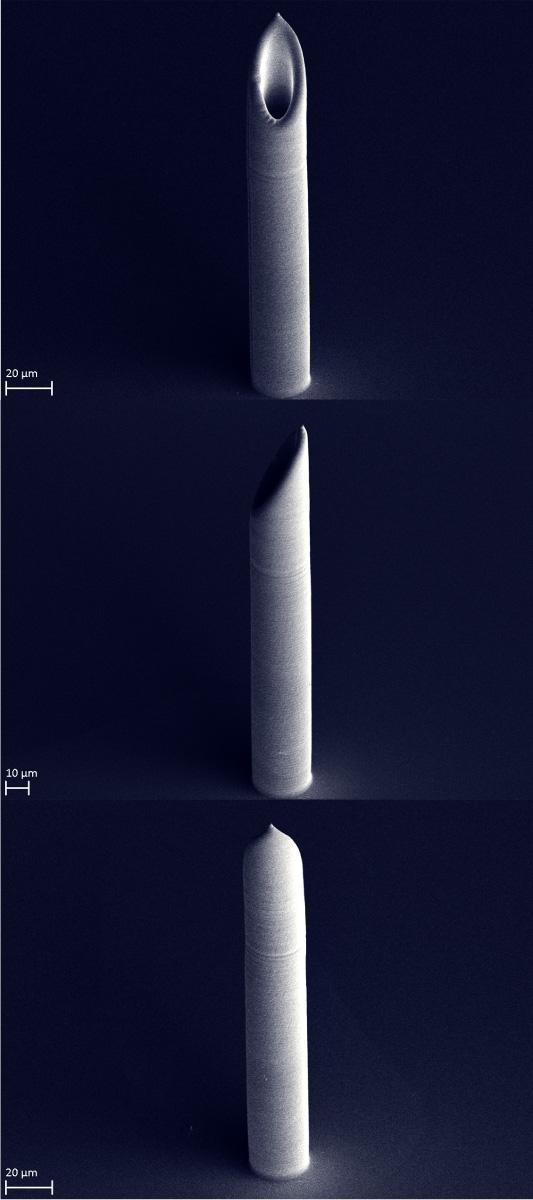

Exaddon's CERES technology enables the following key attributes for microneedle manufacture:

- Hollow microneedles can be printed in various designs and geometries

- Aperture resolution, shape, and positioning can be customized

- High tensile strength

- Not brittle (unlike some polymers)

- Printed structures are naturally biocompatible (copper and gold)

Pictured is a pure copper demo needle printed with the CERES system. The aperture is around 40 µm in height. Overall needle height is 140 µm.

The CERES µAM print system in brief:

- 3D print microscale metal objects directly in situ (eg on a chip surface) via electrodeposition

- Object size range <1 µm to 1000 µm

- Resolution is less than 1 µm

- Room temperature process

- No post processing necessary

- Print in pure metal; copper, gold, nickel, and more

Let's discuss µAM for your application

Explore more microscale 3D Printing use cases: Watchmaking & Copyrighting

Create bespoke structures for identification and exclusiveness