Note: A variation of this post was originally submitted to, & published on, the CMM Magazine website.

Using our unique µAM print technology, Exaddon was able to produce microplugs for AXON' CABLE just 400 µm in height, enabling Axon' to manufacture medical interconnects which will help transform patients' lives.

As an innovative company in the microscale 3D printing of metals, Exaddon was contacted for a new ambitious project by Axon’ Cable, a worldwide leader in specialist cabling and interconnect solutions for high tech applications.

Axon’ Cable needed microscale plugs for tiny connector wires designed for the challenging requirements of various medical and aeronautical applications.

The first intended use case for these microplugs – the tiniest currently known - was in the medical industry. Paraplegic patients require a reliable artificial replacement for damaged nerve fibers, if they are to regain leg functionality once again. This very delicate application meant that Axon’ had to be very mindful of biocompatibility concerns, especially when considering the materials used, how to test the design, and indeed how to design the connector. Put simply, the connection had to be 100% reliable and easy to use.

Two experts tackling a common challenge

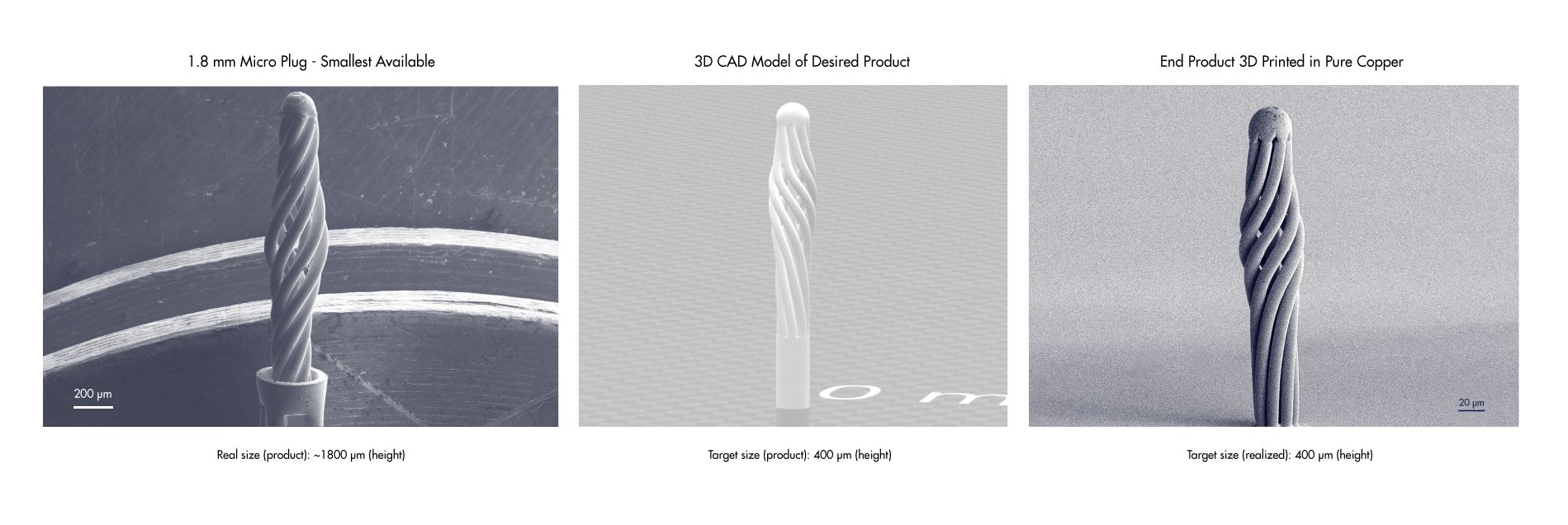

Axon’ Cable required plugs far smaller than is possible with traditional methods of manufacturing. Before the collaboration with Exaddon, the smallest plugs available were 1.8 mm high - though small in general terms, these were far too large for the very sensitive intended application. Axon’ needed plugs just 400 µm in height - over 4x smaller than otherwise available. The dramatic size reduction of course meant a much tinier feature size, and realizing this filigree design was impossible for conventional metal AM techniques such as PBF (powder bed fusion).

Exaddon’s unique additive micromanufacturing (µAM) technology was the answer. The CERES print system utilizes electrochemical deposition to create complex metal structures at micrometer sizes. CERES enables users to produce pure metal objects in complex geometries with submicrometer precision and at room temperature. These objects do not require post-processing – making it uniquely capable of realizing this project.

A New Manufacturing Challenge

The tiny dimensions required by Axon’ Cable were problem for Exaddon's CERES technology, which has printed replicas of Michelangelo’s David just 100 µm tall. Following CAD rendering of the required connectors, 3D printed versions in pure copper were produced with the CERES system. In fact, Exaddon were able to produce plugs just 80 µm high - 5x smaller than Axon’ Cable needed, and 22.5x smaller than the 1.8mm plugs! The actual printing tip used by CERES is in essence a hollow AFM cantilever, and has an aperture just 300nm in diameter.

Considering this, the challenge wasn't producing the actual connectors, but rather the plastic part which protects it, as well as the whole assembly, which is made with various different components.

Whilst designing and creating a microscale connection was challenging project for both Axon’ Cable and Exaddon, this is a real breakthrough in utilizing the unique capabilities of innovative technologies to help paraplegic patients.

Reach out to us and learn more

Discuss your industrial applications or fundamental research challenges

Exaddon and Axon’ Cable – Changing Lives with µAM