Enabling Science & Fundamental Research with µAM

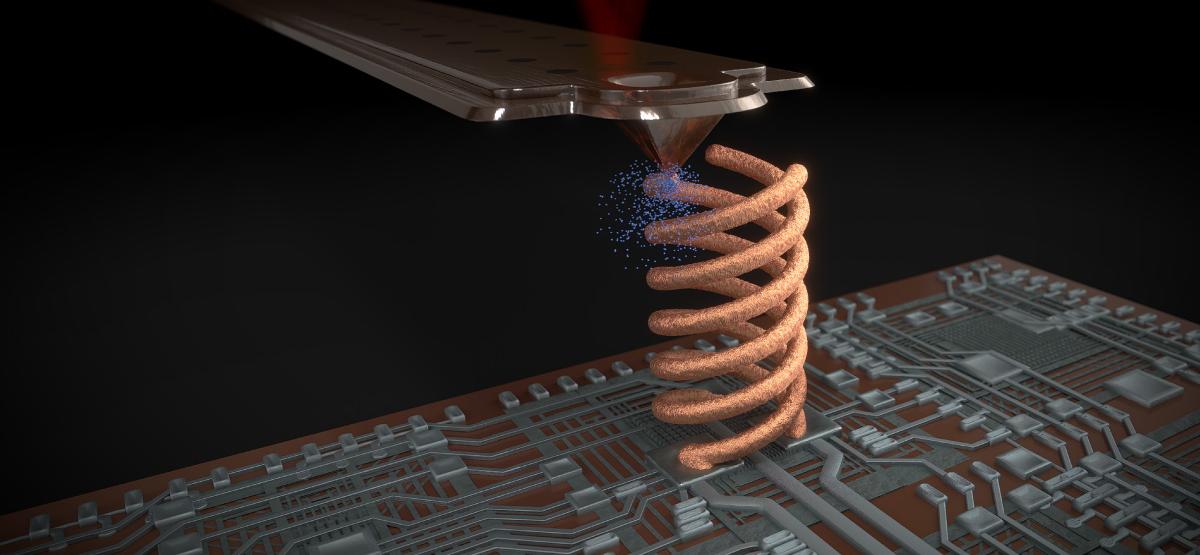

CERES enables unprecedented research possibilities through use of template-free electrodeposition of pure metal. This provides a completely new set of possibilities in materials science studies and fundamental research.

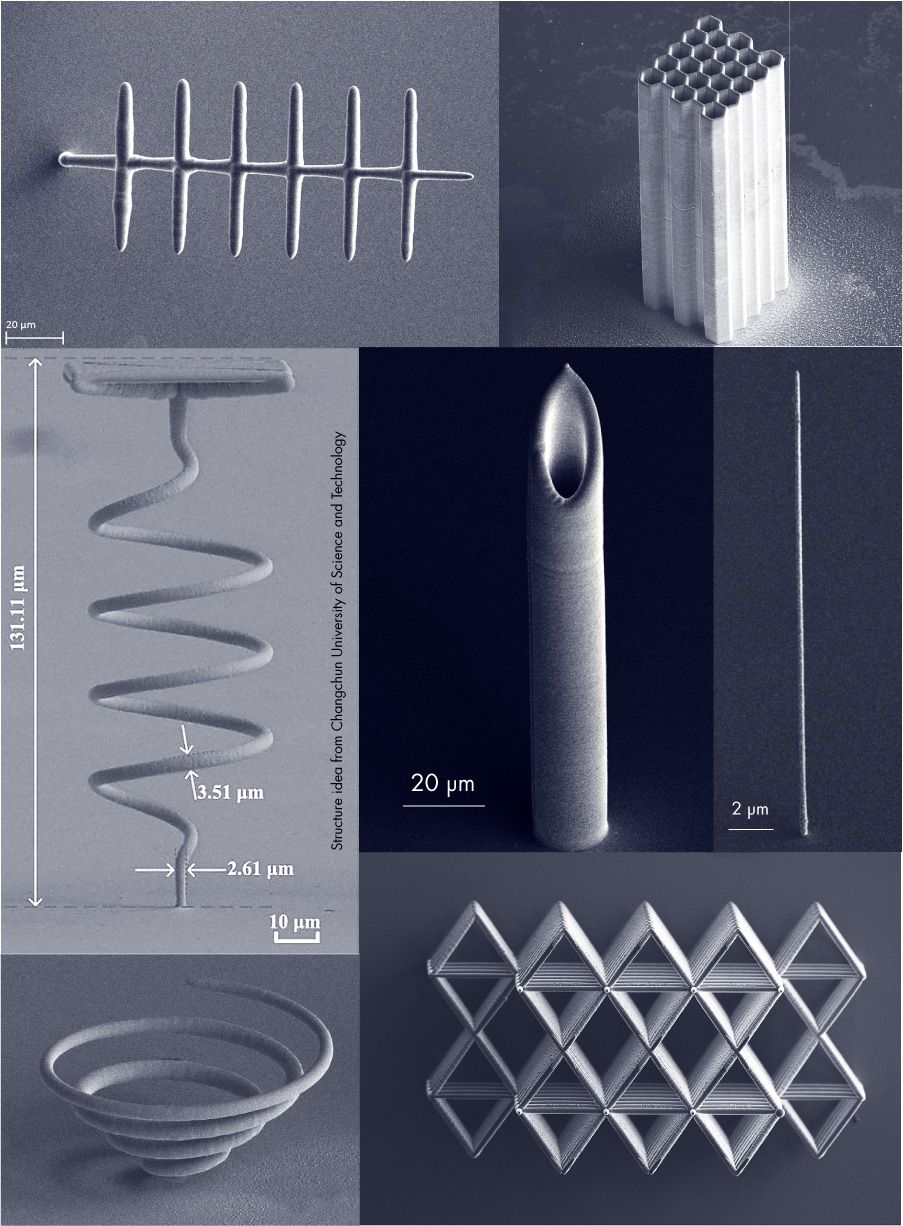

The CERES system can print pure metal microstructures in both simple and complex geometries, thus offering a unique avenue to conducting microstructural characterization research.

Microscale metal parts such as needles, nozzles, and lattices can be created for other applications, and in geometries not possible with other technologies.

The CERES system can print pure metal microstructures in both simple and complex geometries, thus offering a unique avenue to conducting microstructural characterization research.

Microscale metal parts such as needles, nozzles, and lattices can be created for other applications, and in geometries not possible with other technologies.

Advantages:

- Printed structures are made entirely of high mechanical quality metal

- Unprecedented design freedom in microscale sizes

-

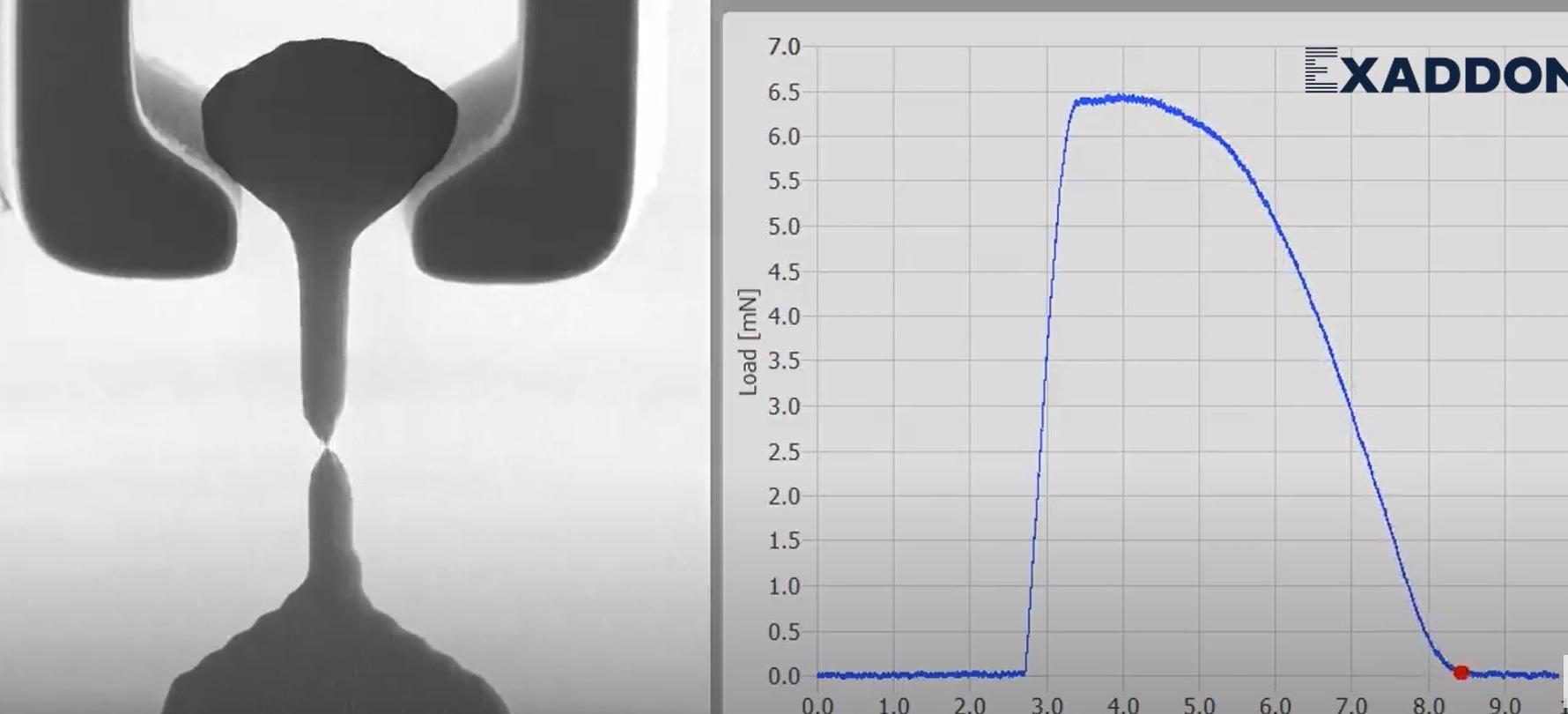

Allows for testing of custom architectures, e.g. microscale test pieces for tensile strength testing.

CERES excels at printing microscale objects, such as:

- Pillars (from <1 µm to 10 µm Ø)

- Coils (e.g. for MEMS switches, surface contacting, cell transfection)

- Lattices

- Hollow needles

-

Arrays of parts (coils, micropillars, needles, etc)

MEMS Research

Exaddon customer Max-Planck Institute use CERES for microstructural characterization studies, and have received a prestigious ERC starting grant from the EU for conducting research in this area.

Materials Science

Extensive testing with Alemnis and EMPA shows the high tensile and yield strength of Exaddon's 3D printed structures.

Conductivity and coating studies show excellent results for resistivity and strength.

Print Novel Structures

Template-free printing on blank or prepatterned substrates enables incredible possibilities. No heat, no lasers, no post-processing.

Next Steps

Real World Example: University of Pisa

Learn how CERES can be used to print

micropillar arrays for cell transfection studies, and projects from life sciences to nuclear physics, photonics, and everything in between.

Talk with Our Team

Reach out to our team now, and discuss your fundamental research projects. We are always open to starting a conversation.

Explore more microscale 3D Printing use cases: Drug Delivery Microneedles

Advance vaccine delivery with 3D Printed microneedle arrays