High Frequency Technologies with µAM - mmWave/5G/THz components

CERES works through local electroplating of ionic metal, allowing you to manufacture minute antennas in geometries impossible for any other technology. Through the incredible precision and control which CERES offers, access to the THz range can be fully realized via our metal 3D printing technology.

Published Research - 3D Printed Micro Helices for mmWave 5G Networks

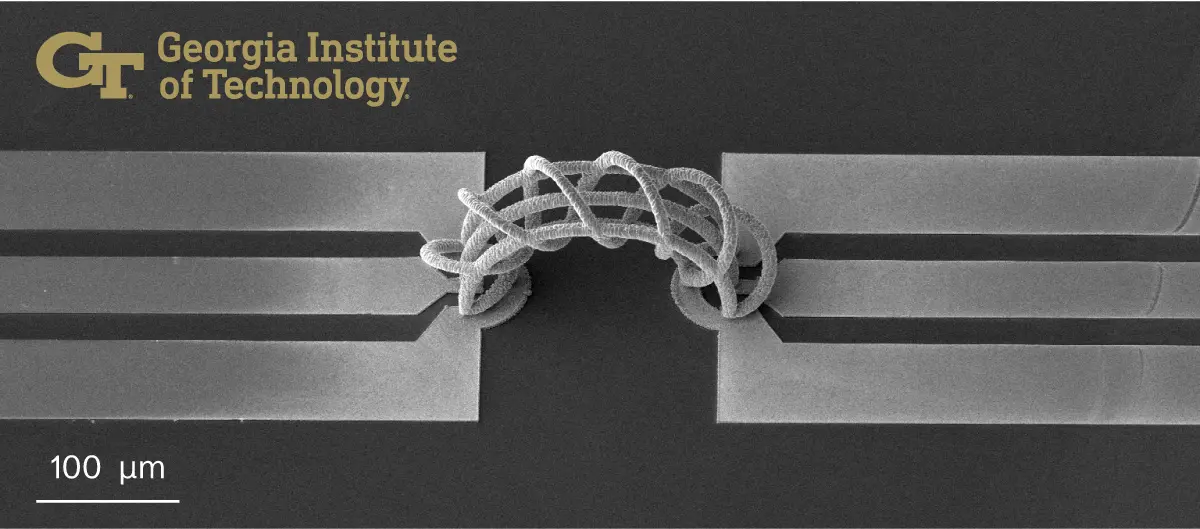

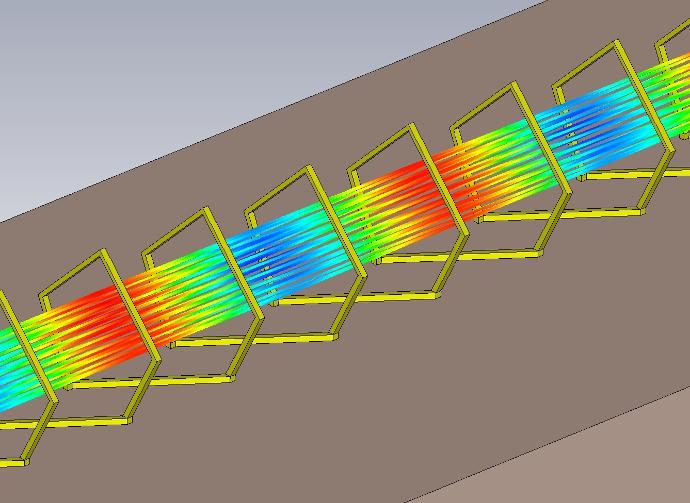

Exaddon's additive micromanufacturing (μAM) technology has been used to fabricate microscale helices for use in travelling-wave tubes (TWTs), a crucial component for 5G networks.

A research collaboration published in IEEE Transactions on Electron Devices, demonstrates the flexibility of

μAM

beyond standard methods, resulting in hard and dense metal properties with excellent conductivity and good surface quality. Published in October 2022, the project was a joint initiative involving Exaddon, Goethe University, and Ferdinand-Braun-Institut.

The unique 3D printing method used by Exaddon's CERES print system allows for the production of helices beyond the current limit of manufacturing, enabling operating frequencies at 66 GHz – ideal for use in telecommunication systems.

This study points towards μAM as a valid means of overcoming the limitations of standard manufacturing methods for microscale slow wave structures, offering an exciting avenue for use of Exaddon's μAM technology within the mmWave/5G arena.

Exaddon Customers Using CERES for High Frequency Research

Georgia Tech Institute for Matter & Systems

Georgia Tech created a first-of-its-kind shielded interconnect design in geometries unachievable by other fabrication methods, for sub-THz applications.

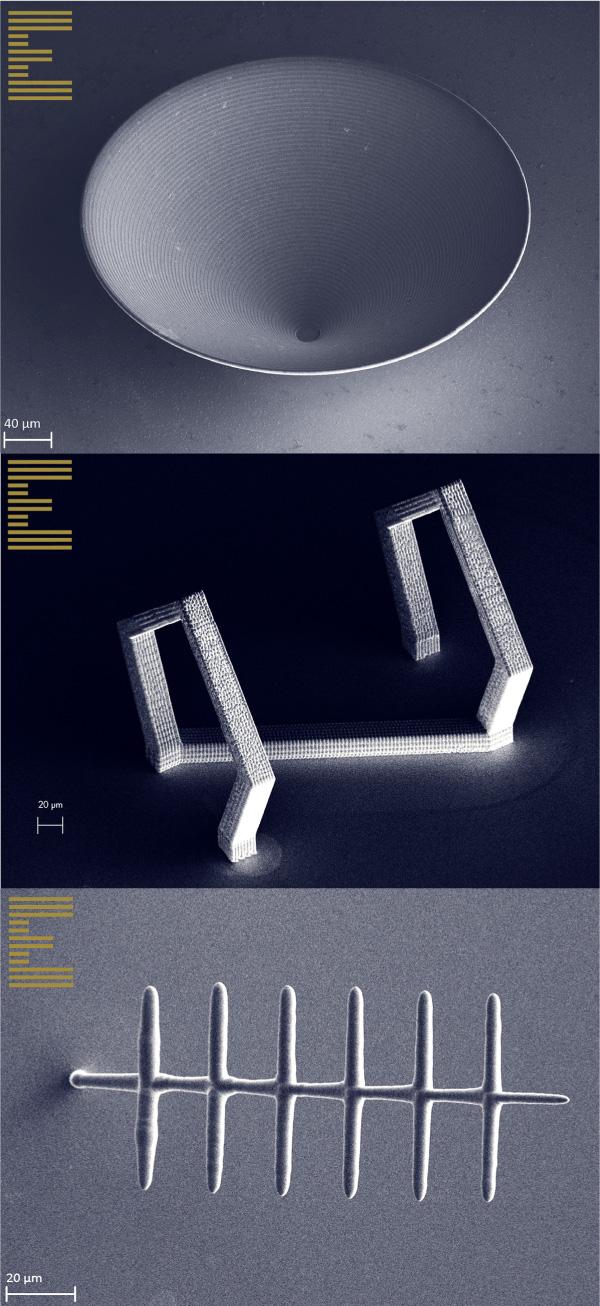

Karlsruhe Institute for Technology

Previously impossible THz free-form antennas as well as miniaturized and low-loss connection technology will be realized with the new CERES system.

Cardiff University

Cardiff University is investigating coplanar waveguides on GaN-on-SiC for future mmWave applications.

Read the Blog PostFerdinand Braun Hochschule

The FBH microwave department and III-V electronic labs are involved in key research relating to millimeter waves and THz components for communications and radar.

Read the Blog PostExplore more microscale 3D Printing use cases: Microcoils

3D Print microcoils and springs in microscale dimensions