Our Products.

Next Generation Wafer Probing

Our Products.

Next Generation Wafer Probing

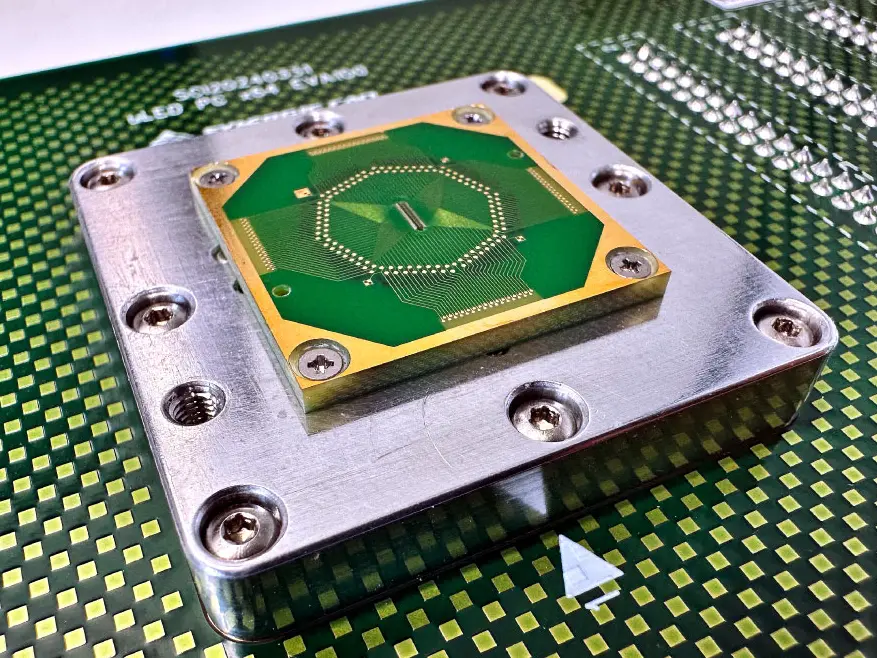

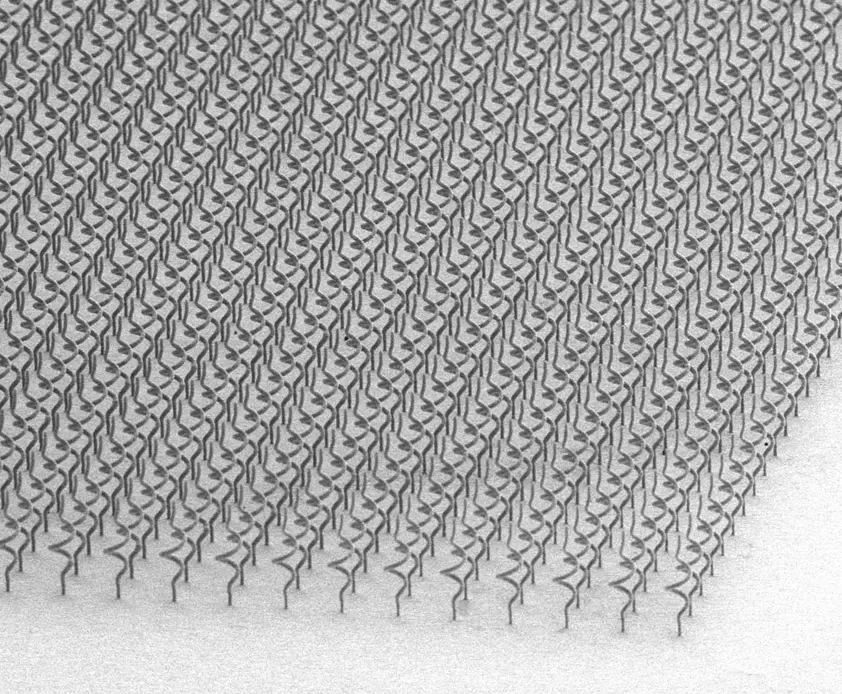

Exaddon currently offers three product options for ultrafine pitch, high-precision wafer probing applications. The modular design and exceptional precision of micro3D printing deliver unmatched customization and accuracy.

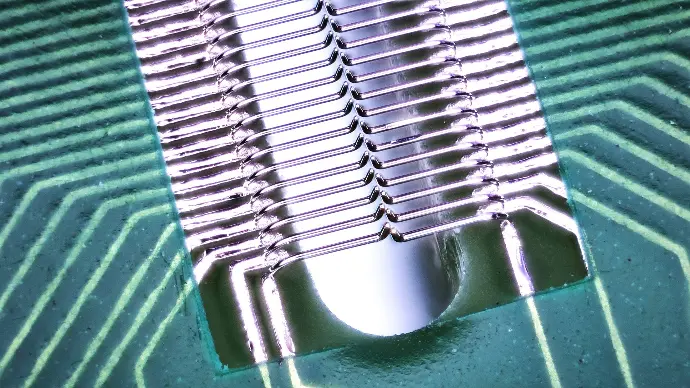

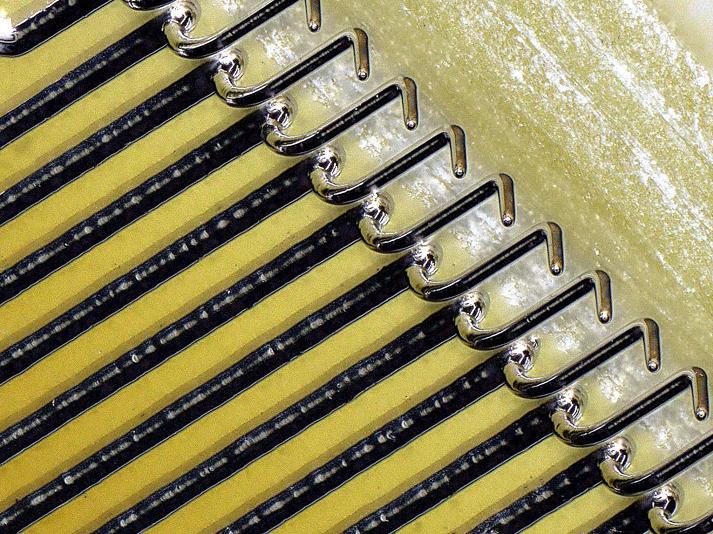

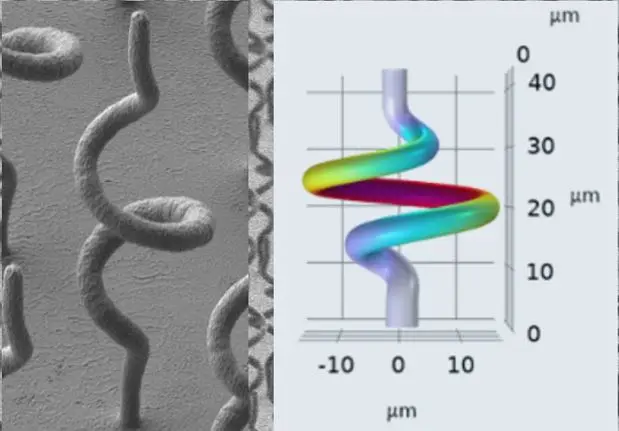

The probes are micro3D printed in pure copper, which offers excellent conductivity. These are then coated in an optimized nickel-alloy for excellent mechanical strength, contact reliability and durability. The shape and diameter can be tailored per application requirements.

Please speak to us directly to learn more about our probe head solutions. Through ongoing collaboration with probe card suppliers, we can support customers with turnkey probe card solutions, or customized, alternative probing solutions.