Whilst our proposed cover suggestion for Micromachines 11.1 (above) wasn't accepted, our paper has received global attention

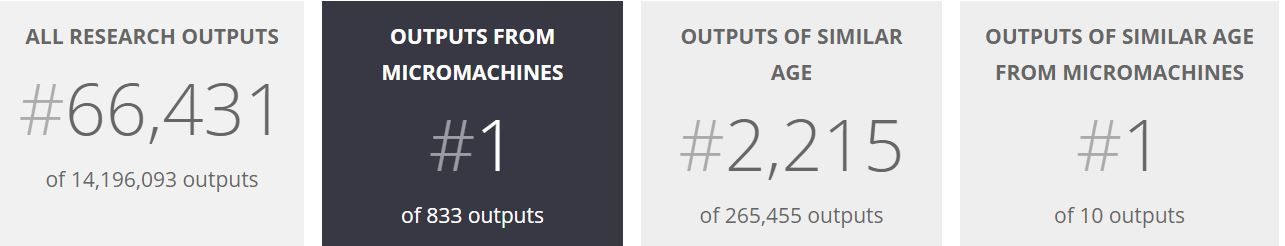

Since its publication just before Christmas, our paper has become the #1 ranked output all-time from Micromachines, as calculated by Altmetric.

Furthermore, the paper lies in the top 5% of all research outputs ever tracked by Altmetric, of which there are over 14 million to date!

The paper has received global publicity thanks to coverage on TechCrunch, Forbes, TechRadar, CNET, Gigazine, and of course ETH News.

The paper details the capabilities of our unique CERES print system, and its capacity to print complex objects out of pure metal at micrometer sizes, without any post-processing, and at room temperature.

To learn more about our CERES system, please download the datasheet here. Further research papers involving the CERES system is listed in our publications page.

The full paper is available on the Micromachines website here.

Please visit our Publications page to see our other research papers.

About Exaddon AG

We provide high-precision and innovative additive micromanufacturing solutions for technology visionaries and companies aiming to be at the forefront of innovation.

Our unique CERES printing system is designed for researchers and scientists to conduct additive micro-manufacturing (µAM) of metals on the micrometer scale. CERES can print complex micro metal objects with nanometer resolution, in sizes from 1 µm to up to 1000 µm, at room temperature and without the need for post-processing.

Additive Manufacturing of Sub-Micron to Sub-mm Metal Structures with Hollow AFM Cantilevers