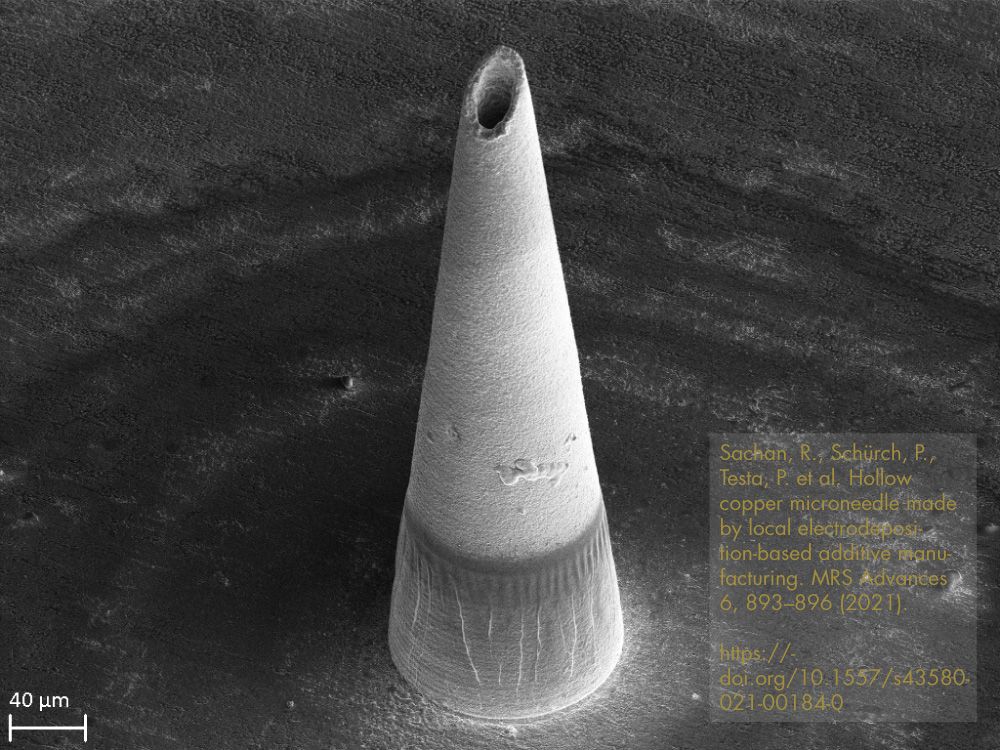

In a research collaboration between Exaddon, North Carolina State University State University and the University of North Carolina at Chapel Hill, hollow microneedles were created out of copper using Exaddon's local electrodeposition-based additive manufacturing process.

Published in Materials Research Society Advances, the study demonstrates the potential use of Exaddon's pioneering metal additive micromanufacturing (µAM) technology to manufacture hollow copper needles for drug delivery.

Paper reference: Sachan, R., Schürch, P., Testa, P. et al. Hollow copper microneedle made by local electrodeposition-based additive manufacturing. MRS Advances 6, 893–896 (2021). Springer

Using 3D Printing for Transdermal Drug Delivery

Pictured is an Exaddon demo needle printed in pure copper with the CERES system. The aperture is around 40 µm in height. Overall needle height 140 µm.

The CERES µAM print system in brief:

- 3D print microscale metal objects directly in situ (eg on a chip surface) via electrodeposition

- Object size range <1 µm to 1000 µm

- Resolution is less than 1 µm

- Room temperature process

- No post processing necessary

- Print in pure metal; copper, gold, nickel, and more

Exaddon Research in MRS Advances - Microneedles for Drug Delivery