The purchase and installation of the CERES system is a great step forward in enabling further understanding of miniaturized materials.

A long time collaborator with Exaddon, Group Leader Rajaprakash Ramachandramoorthy is using our CERES system for investigations in multiple fields.

We are very excited to see the forthcoming research from Raj, Sung-Gyu Kang, and Bárbara Bellón!

CERES can print 99% density copper structures (amongst other metals) with submicrometer resolution, at room temperature. These capabilities set it apart from other microscale AM technologies such as Two-Photon Polymerization (2PP), allowing CERES operators to print microscale metal structures directly in situ, such as lattices, micro pillar arrays, needles for neural interfaces, helices, or waveguides, directly on a chip surface.

Discover CERES uses cases in precision applications

Unlock your industrial applications or research challenges

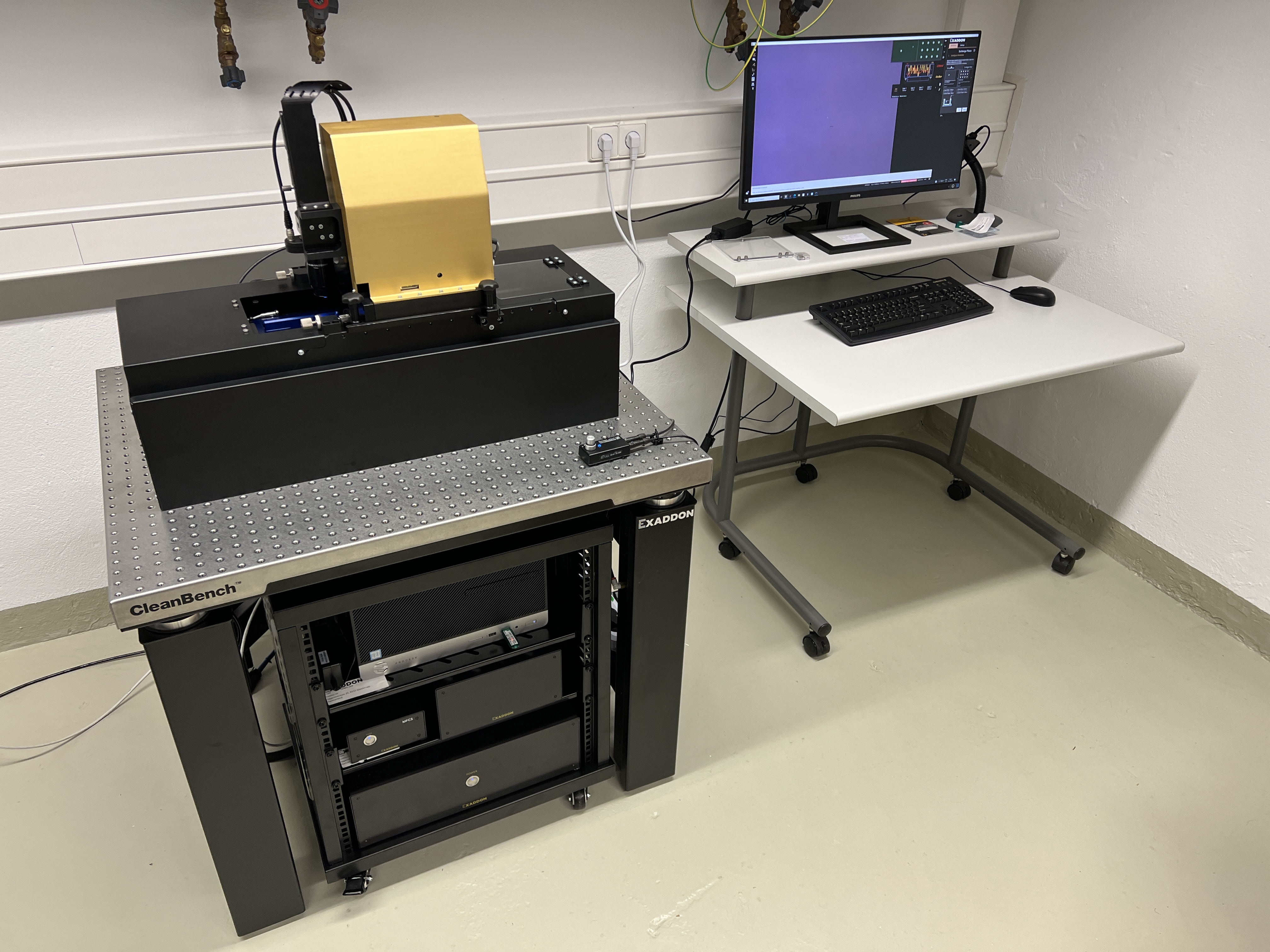

Max-Planck-Institut für Eisenforschung Purchase Exaddon CERES µAM Print System