Additive Micromanufacturing Further Establishes Itself

A 2019 has been a busy year for the 3D printing/additive manufacturing industry, and that is especially true for additive micromanufacturing. Whilst AM has long since gained market maturity, use cases are still being explored, let alone realized at a scale comparable to conventional manufacturing techniques.

At the micrometer scale, more companies are entering the space, and due to the raw and developmental nature of some of the technologies involved, the use cases remain open-ended.

A number of companies are now targeting the nano-/ micro-additive manufacturing arena, and big differences exist in how they approach the physical process of µAM. Many of these companies, like Exaddon, have their roots in research departments, and their exact AM processes differ according to the focus and investigations of the original research departments.

Exaddon x ETH Zurich Research Collaborations

We have been heavily involved in furthering our R&D capacity through collaboration with research institutes, and commercial partnerships with industry. Our most recent paper in Advanced Engineering Materials received excellent feedback during the peer review process:

"An excellent manuscript going beyond current state of the art in terms of printing techniques."

We have also just published in Micromachines, focusing again on a collaboration between our engineers and the team at ETH LBB, which has been similarly well-received.

A number of companies are now targeting the nano-/ micro-additive manufacturing arena, and big differences exist in how they approach the physical process of µAM. Many of these companies, like Exaddon, have their roots in research departments, and their exact AM processes differ according to the focus and investigations of the original research departments.

Exaddon - Additive Micromanufacturing of Metals

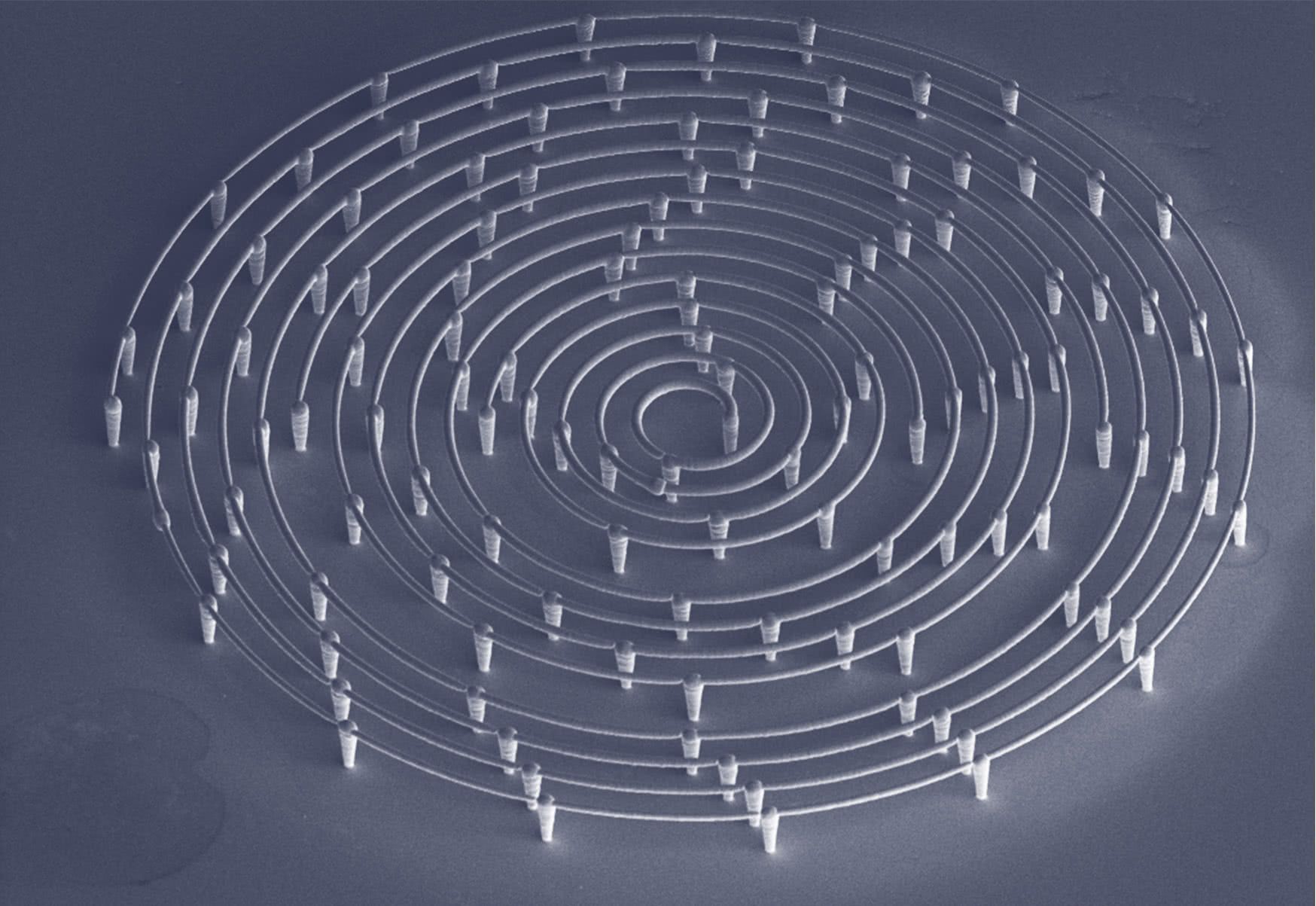

Exaddon specializes in printing complex metal objects at micrometer scale and as the industry continues to grow, 2019 has seen dramatic changes for us. In our first year since our spin-off from Cytosurge AG, we have seen first-hand how our printing technology remains unique in the industry.

We exhibited at Formnext 2019 – the largest additive manufacturing conference in the world with some 35,000 attendees and 850 exhibitors – and spoke with many visitors and companies alike.

Other companies are printing polymers at micro- and nano- level, but we are the only company printing at such sizes with metals. This opens the doors to a unique set of applications which necessarily cannot be addressed by other µAM techniques/technologies.

So far we have focused primarily on printing pure copper, though we can also print in gold, silver, and platinum. Due to its excellent conductivity and widespread use in electronics, copper remains our preferred choice.

Look out for future blog posts describing the details of each of the distinct methods of µAM, such as TPL, laser sintering, aerosol jet, and an analysis of how their action and applications compare to ours.

About Exaddon AG

We provide high-precision and innovative additive micromanufacturing solutions for technology visionaries and companies aiming to be at the forefront of innovation.

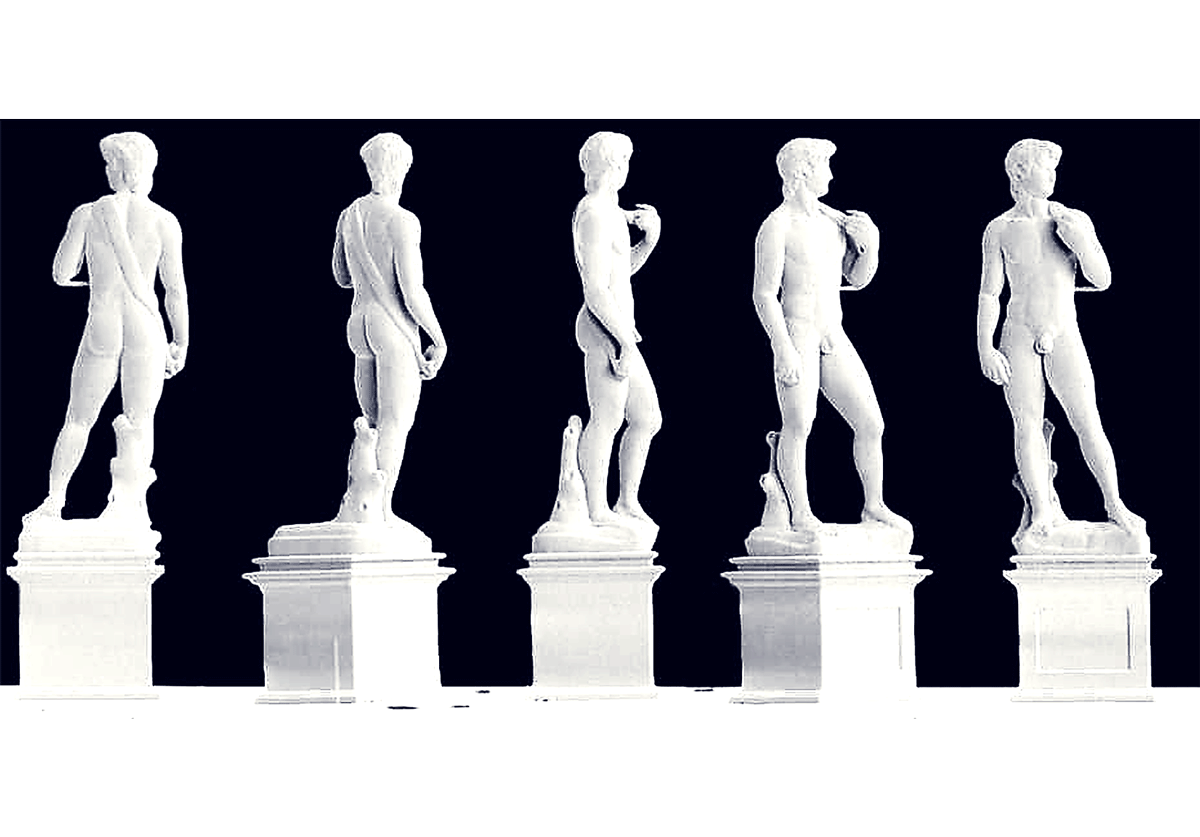

Our unique CERES printing system is designed for researchers and scientists to conduct additive micro-manufacturing (µAM) of metals on the micrometer scale. CERES can print complex micro metal objects with nanometer resolution, in sizes from 1 µm to up to 1000 µm, at room temperature and without the need for post-processing.

Exaddon - 2019 Year in Review