Micro3D research.

Advance your research with Exaddon micro3D printing

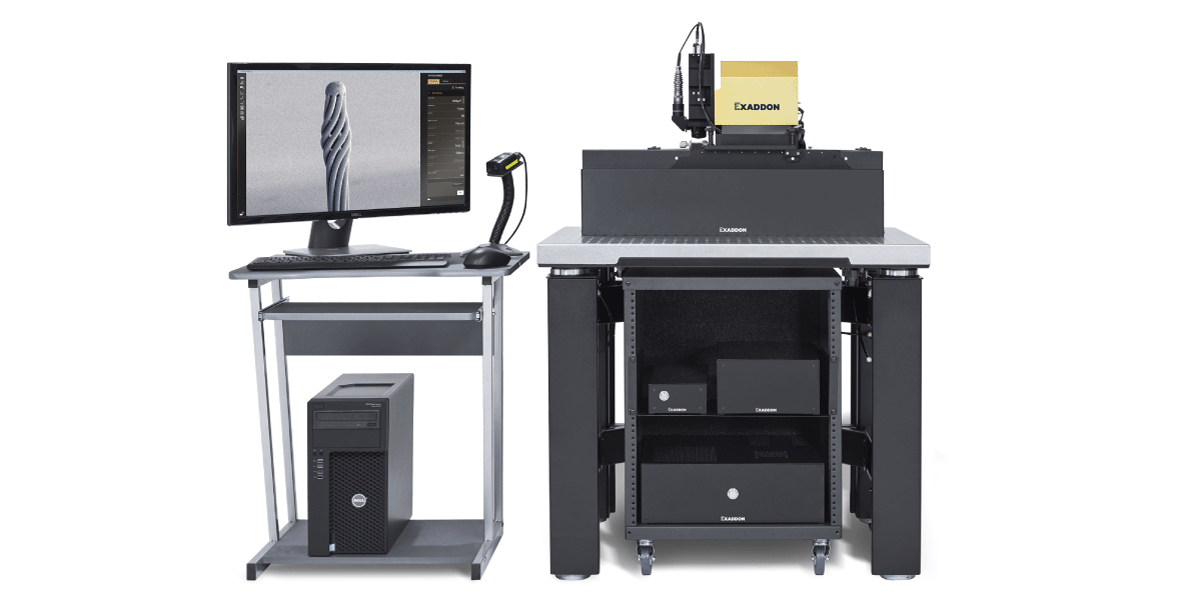

Our CERES system brings our unique micro3D printing technology to universities and research institutions in a convenient, standalone printer. With CERES, research staff can 3D print pure metal objects down to 1 µm in size.

Unlock your next research breakthrough with Exaddon microscale 3D metal printing; browse the system information and use cases below.

<1 µm to 1000 µm

Possible object size

Print Pure Metals

Print directly in Cu, Au, Ni, Ag, Pt

<1 µm Resolution

Minimum feature size

Print in Place

Directly on pre-patterned chips.

No heat, no lasers, no post-processing

Exaddon Print Process

Exaddon's technology uses template-free electrochemical deposition to create free-standing metal structures. The fundamentals of this process are outlined in the CERES datasheet below.

Exaddon has extensively investigated the material properties of our printed structures.

Several of our customers focus their research on characterizing the micromechanics of CERES-printed objects. The results can be viewed in the material properties whitepaper here.

Download CERES System Datasheet

Exaddon CERES Use Cases

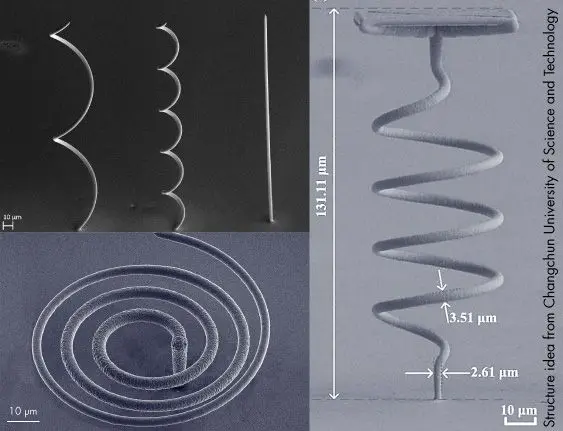

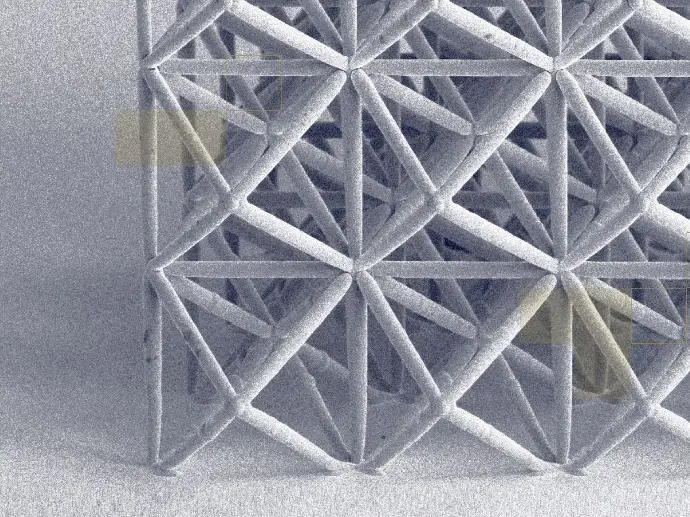

The Exaddon CERES µAM Print System specializes in printing free-standing objects at the lower end of the microscale (e.g. 1 µm - 300 µm in size), such as pillars, coils, and lattices. With no heat, no lasers, and no post-processing, CERES delivers microscale pure metal objects in a single workflow. With excellent conductivity (87% of bulk copper) and tensile strength, printed structures are suitable for a range of applications.

Ultimately, the best way to understand the capabilities of the CERES system is to explore the use cases of our customers. Visit our publications page to browse the diverse research fields we're involved in, or look through the list of use cases below.

Neural Interfaces

Print high conductivity, high aspect ratio (100:1) gold or copper structures directly on prepatterned traces or contact pads with micrometer accuracy. Exceptional conductivity and mechanical strength are ideal for neural applications.

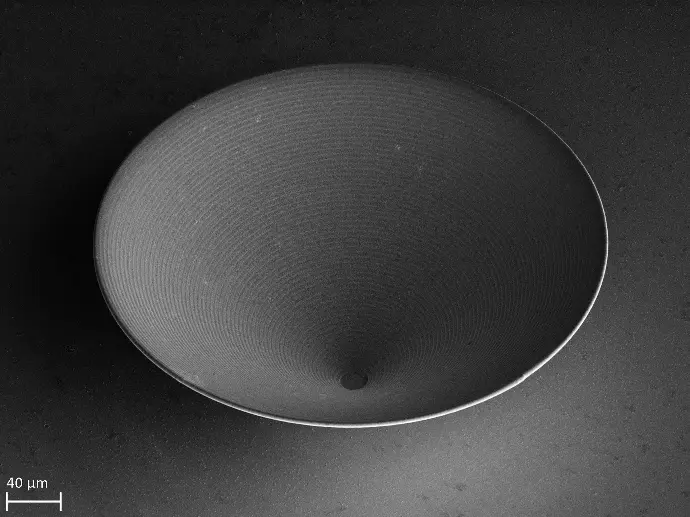

High Frequency Components

The exceptional surface smoothness of CERES-printed objects is ideal for high frequency applications. Seamless merging with the target surface ensures minimal signal disturbance.

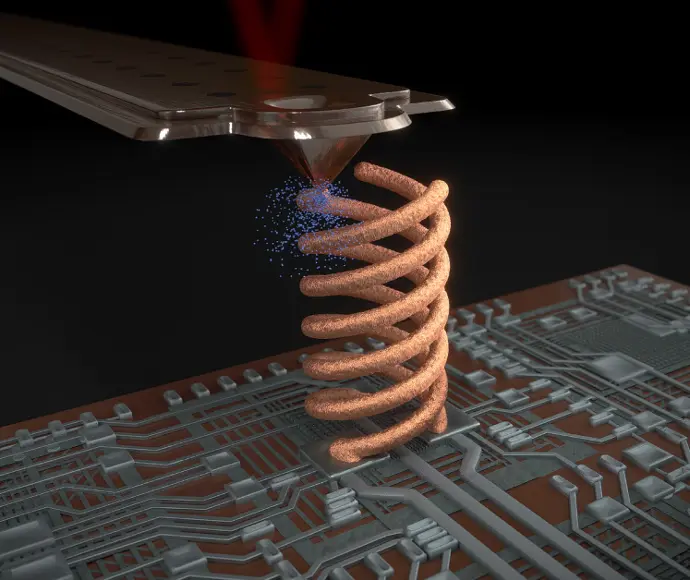

Microcoils

From MEMS to micromechanics, microcoils are crucial structures. Exaddon's unique print-in-place technology is perfectly suited to printing coils directly where needed. Strand diameter can be changed on the fly.

Material Science & Novel Research

Use CERES for 3D printing pillars, lattices, and other test pieces for microstructural characterization. Explore the exceptional conductivity and tensile strength of printed structures.

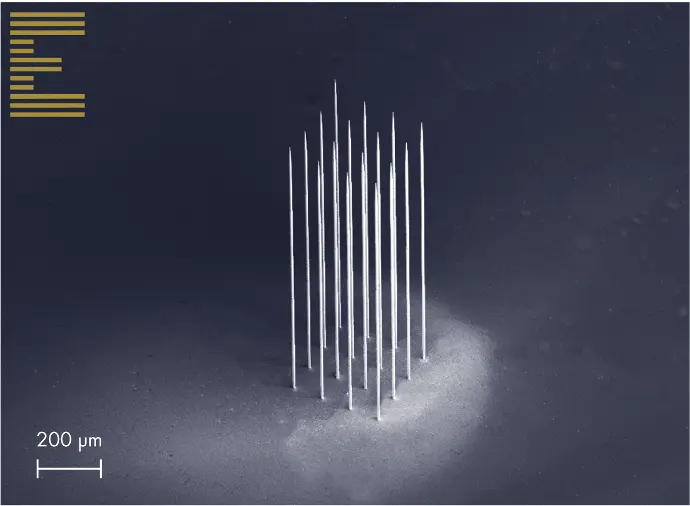

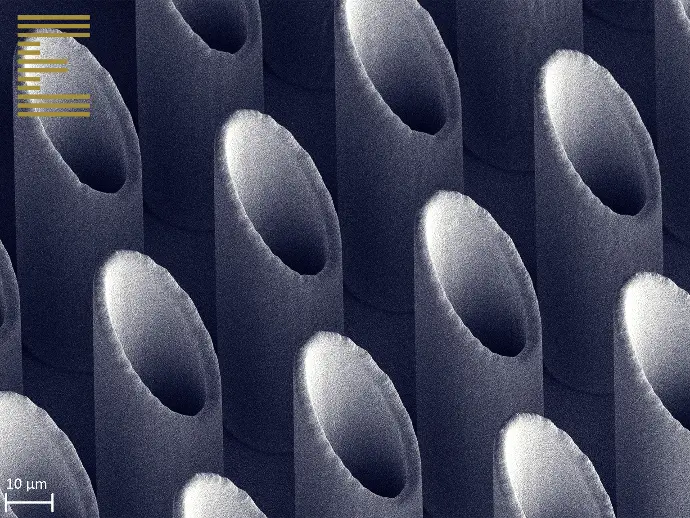

Drug Delivery Microneedles

Print arrays of biocompatible microneedles in pure copper or gold, ideally suited for transdermal drug delivery. High (submicrometer) resolution ensures incredible accuracy.

Our Research Partners

CERES SYSTEM MATURITY

Standardized Workflows

Comprehensive, tested print workflows designed for ease and optimal user experience

Proprietary Software

Our CAPA software is custom developed for the CERES 3D printing system and its printing workflows

Online User Manual

The regularly updated, comprehensive user manual guides research staff through every step, from printing to maintenance

CUSTOMER TESTIMONIALS

Advance your application with Exaddon 3D Printing

Contact us today!