CERES µAM System

Our CERES µAM system prints pure metal at room temperature via electrodeposition. Thanks to our intensive R&D processes, CERES prints ready-to-use parts with no post-processing stages necessary; instantly cutting out what is a huge resource drain for many AM technologies.

We are able to fully focus our attention on printing high quality pure metal without concern for finishing steps after the prints. Further, as the print process occurs at room temperature, there is no material deformity due to heating or cooling, thus ensuring high material integrity.

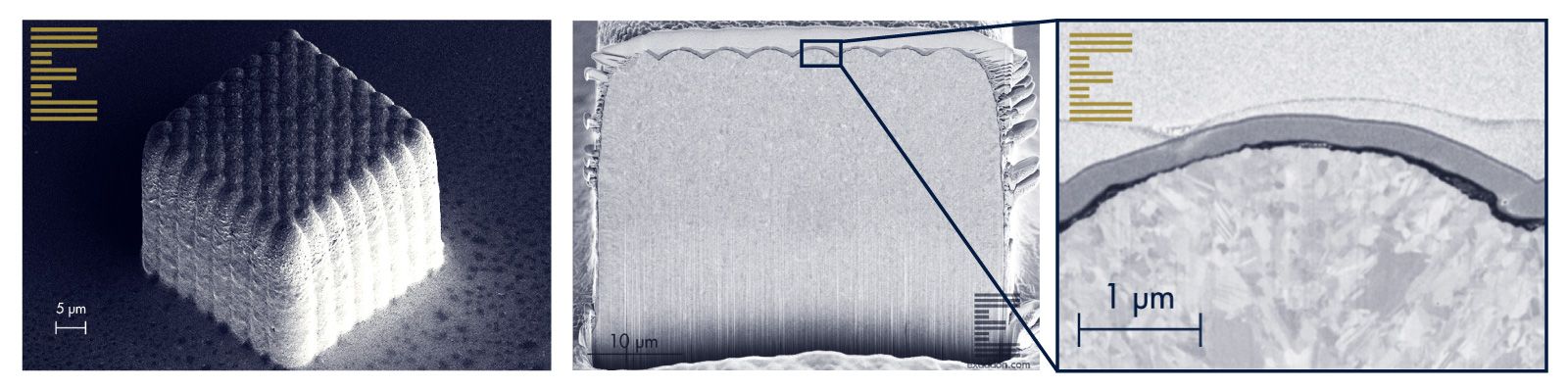

Uniformity of Grain Structure

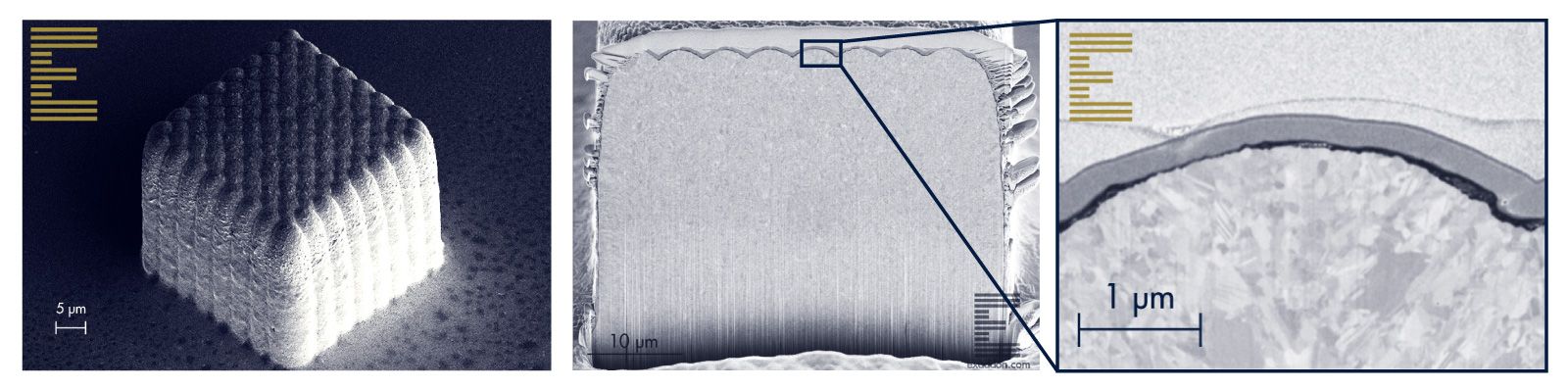

As part of a voxel spacing/merging test, we printed an array of copper micropillars in close proximity, such that they merged into an approximate cube (roughly 50 µm diameter). We then sliced it with a Focused Ion Beam (FIB) in order to assess the homogeneity of the grain structure.

Whilst the external surface in the left image shows the relief of the individual pillars, the cross-section SEM on the right shows that the deposited material is nicely uniform and homogeneous inside, and there are no visible traces of the individual voxels.

This homogeneity of grain structure is essential in many use cases, such as heat-sensitive applications. Low porosity is also crucial, especially in uses such as wire bonds and defect repairs on microelectronic applications, where electrical conductivity is paramount.

Our printed microcrystalline copper has > 99% density

Conductivity of printed structures is close to that of bulk copper

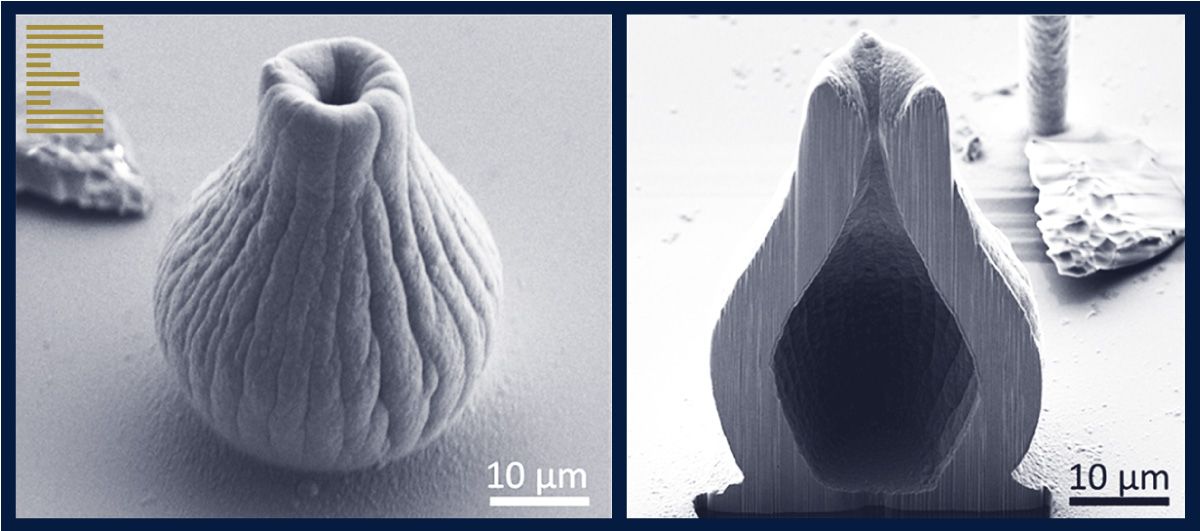

Wall Diameter Consistency of Hollow Objects

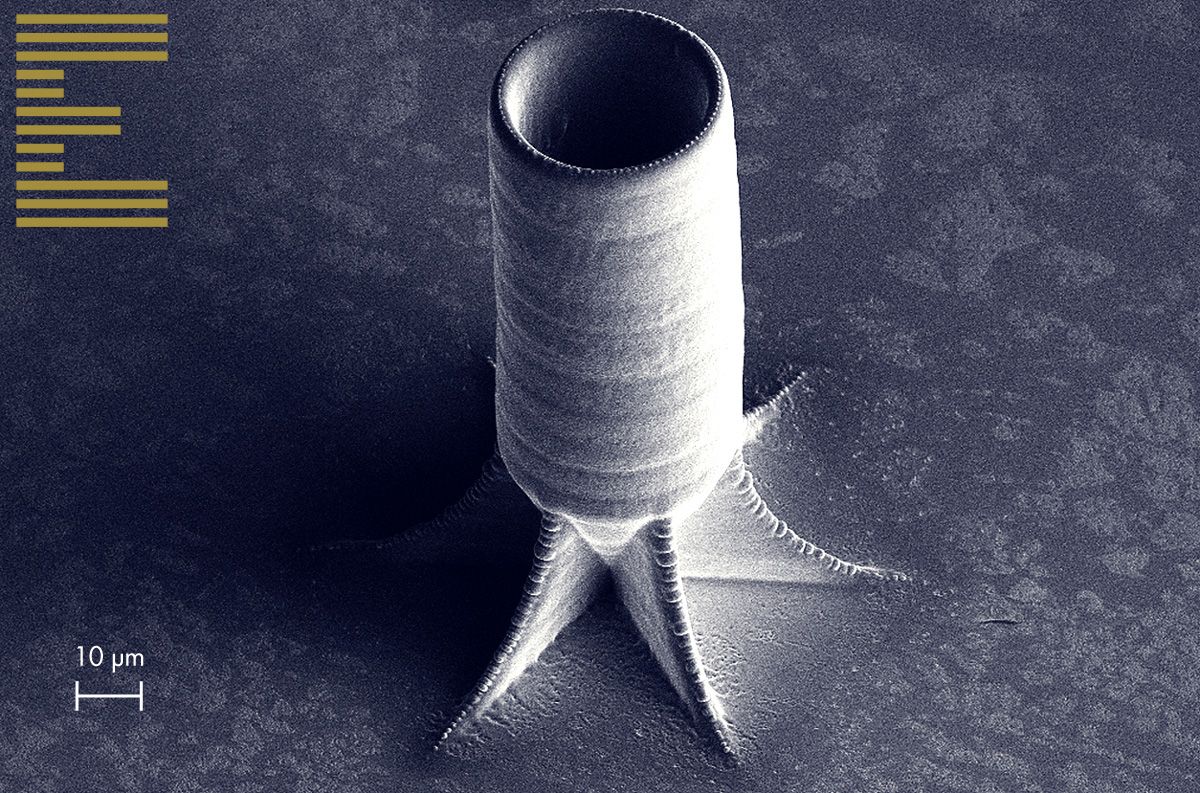

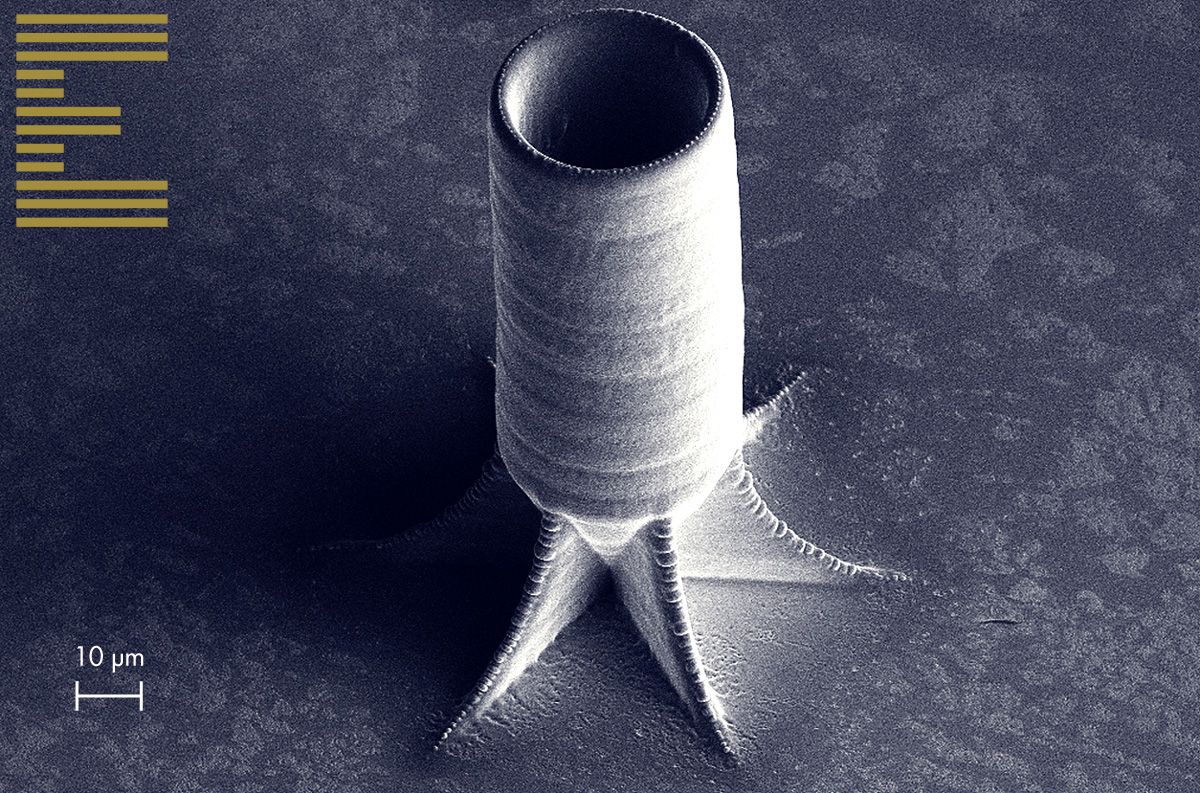

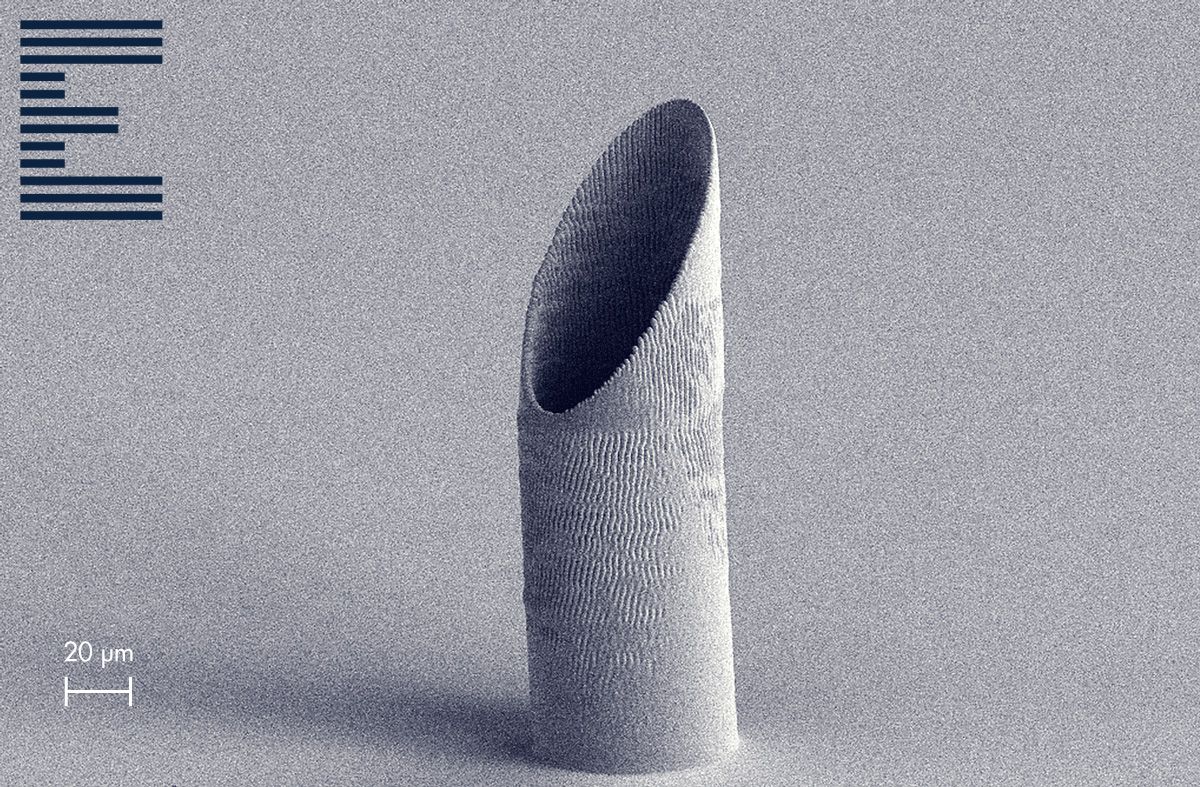

CERES allows for the printing of hollow volume objects, such a microneedles and miniature “vases”. The SEM images in the carousel below show that these objects have regular internal surfaces, just as per the outside, as well as consistent wall diameters. Scroll through to see the FIB cross-section of a hollow vase.

Substrate Adhesion

The video shows a copper spring undergoing mechanical hysteresis testing:

The copper is mechanically stable

The copper behaves elastically

There is good adhesion to the substrate (gold)

Reach out to us and learn more

Discuss your industrial applications or fundamental research challenges

Exaddon 3D Printing Material Properties