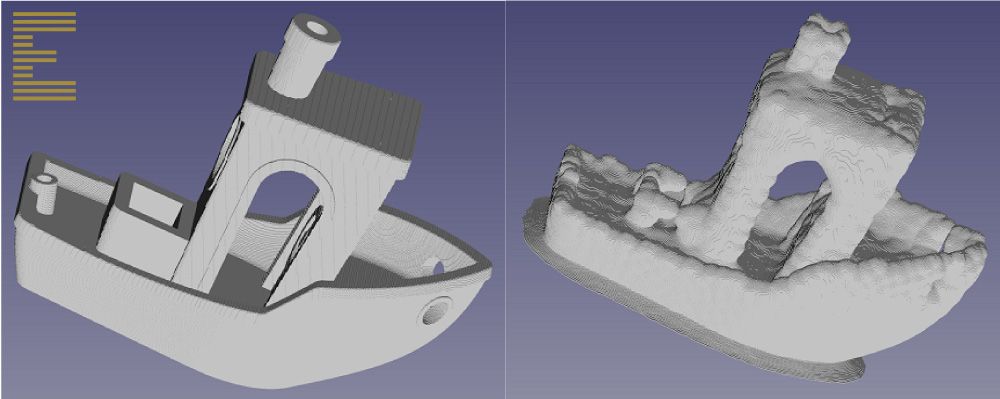

What will an object look like when it has been printed with µAM?

What degree of tolerance can a user expect?

These questions are central to additive manufacturing, especially at the microscale. Our engineering team turned to 3DBenchy, the mainstay test piece of amateur 3D print enthusiasts everywhere, to test a new simulator designed to answer these very questions.

The cartoonish boat design has found fame through its unique combination of shapes, planes, and intricate features, presenting any AM system with a challenge. This holds true at the nano- and microscales, just as it does at more conventional size ranges.

Whilst 3DBenchy has previously been realized in nanoscale through use of 2PP, and in macroscale dimensions via countless means, we were not using the design as a test of how small we could print, but rather as a recognizable means of testing new functionality in our CERES system.

The image above shows some of the v0.1 renderings from our quest to perfect the voxelization of design files. This process seeks to optimize for print time and submicrometer resolution, as well as of course showing the user what the printed object will look like. This algorithm becomes the print algorithm - what you see is what you will get.

The R&D team are already at v0.5, and let's just say the results are impressive!

Questions? Reach out to us and learn more.

Discuss your industrial applications or fundamental research challenges

Developing a µAM Simulator